What is ESD plastic?

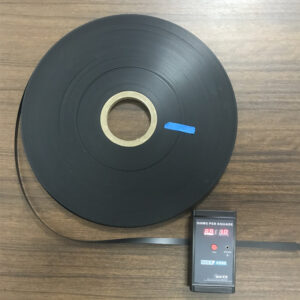

ESD plastic is an antistatic plastic material with anti-static function. The full name in English is “Electrostatic Discharge (ESD) plastic materials”. Its main characteristics are to prevent or reduce the generation and accumulation of static electricity and quickly conduct static electricity to prevent static electricity from damaging sensitive electronic components and equipment.

ESD plastic is usually realized by adding some special conductive components to plastic raw materials, such as carbon fiber, carbon black, antistatic masterbatch, etc. These conductive components form a conductive network in the plastic so that the charges on the surface and inside of the plastic cannot accumulate, thereby achieving an anti-static effect. Common ESD plastics include PA (polyamide), PC (polycarbonate), ABS alloy, POM (polyoxymethylene), PP (polypropylene), etc. Its colors are mostly black, natural color, transparent, etc.

ESD plastic is widely used in industries that are sensitive to static electricity, such as electronics, electrical, communications, and semiconductors. For example, in the electronic manufacturing process, pallets, boxes, packaging bags, etc. made of ESD plastic materials can prevent electronic components from being affected by static electricity during transportation, storage, and processing; in semiconductor production equipment, ESD plastic materials can be used to manufacture some components to prevent static electricity from damaging semiconductor chips.

Where is ESD plastic used?

Electronic manufacturing field

- Electronic component production workshop: In the process of producing integrated circuits, transistors, diodes, capacitors, resistors, and other electronic components, ESD plastic materials can be used to make storage trays, transport boxes, turnover boxes, etc. of components. These containers can prevent electronic components from being affected by static electricity during movement and storage, prevent components from being broken down or damaged by static electricity, and ensure the performance and quality of components.

- Electronic product assembly line: For example, on the assembly line of electronic products such as mobile phones, computers, and tablets, ESD plastic materials can be used to make assembly tools, fixtures, and jigs. These tools will not generate static electricity when in contact with electronic products, ensuring the smooth progress of the assembly process, and also protecting the internal circuits of electronic products from static electricity interference.

Semiconductor manufacturing field

- Wafer manufacturing: Wafers are the basic materials of semiconductor chips. In the manufacturing process of wafers, the control requirements for static electricity are very strict. ESD plastic materials can be used to make wafer carriers, handling tools, etc. to prevent static electricity from damaging wafers and affecting the manufacturing quality of chips.

- Chip packaging: Chip packaging is the process of cutting a wafer into individual chips and encapsulating the chips in a shell. ESD plastics can be used to make molds, fixtures, trays, etc. for chip packaging to ensure the electrostatic safety of the chip during the packaging process.

Medical equipment field

- Medical electronic equipment: such as electrocardiographs, electroencephalographs, blood pressure monitors, blood glucose meters, and other medical electronic equipment, which contain a large number of electronic components and circuits and are very sensitive to static electricity. ESD plastic materials can be used to make shells, control panels, connecting wires, and other parts of these devices to prevent static electricity from affecting the normal operation of the equipment and ensure the safety of patients.

- Medical laboratories: In medical laboratories, various electronic instruments and equipment are often used, such as centrifuges, microscopes, PCR instruments, etc. ESD plastic materials can be used to make laboratory work surfaces, instrument shells, experimental equipment, etc., to provide laboratory personnel with a static-safe working environment.

Automotive electronics field

- Automotive electronic control system: The automotive electronic control system is one of the core components of automobiles, including the engine control system, brake control system, airbag control system, etc. ESD plastic materials can be used to make shells, connectors, wiring harnesses, and other parts of automotive electronic control systems to prevent static electricity from affecting the normal operation of electronic control systems and improve the safety and reliability of automobiles.

- Automotive electronic entertainment systems: such as car audio, car navigation, car TV, and other automotive electronic entertainment systems, also need to use ESD plastic materials to make related components to prevent static electricity from affecting the normal use of the entertainment system.

Aerospace field

- Aircraft electronic equipment: Electronic equipment on aircraft is very sensitive to static electricity, such as flight control systems, navigation systems, communication systems, etc. ESD plastic materials can be used to make aircraft electronic equipment shells, control panels, connecting wires, and other components to prevent static electricity from affecting the flight safety of aircraft.

- Satellite manufacturing: When satellites are operating in space, they will be affected by various radiation and static electricity. ESD plastic materials can be used to make satellite electronic equipment shells, solar panel frames, and other components to ensure the normal operation of satellites.

Precision instrument field

- Optical instruments: Optical instruments such as microscopes, telescopes, cameras, etc., which contain a large number of optical lenses and electronic components, are very sensitive to static electricity. ESD plastic materials can be used to make optical instrument shells, lens mounts, focusing devices, and other components to prevent static electricity from affecting the performance of optical instruments.

- Measuring instruments: Measuring instruments such as multimeters, oscilloscopes, signal generators, etc. also need to use ESD plastic materials to make related components to prevent static electricity from affecting the accuracy of measurement results.