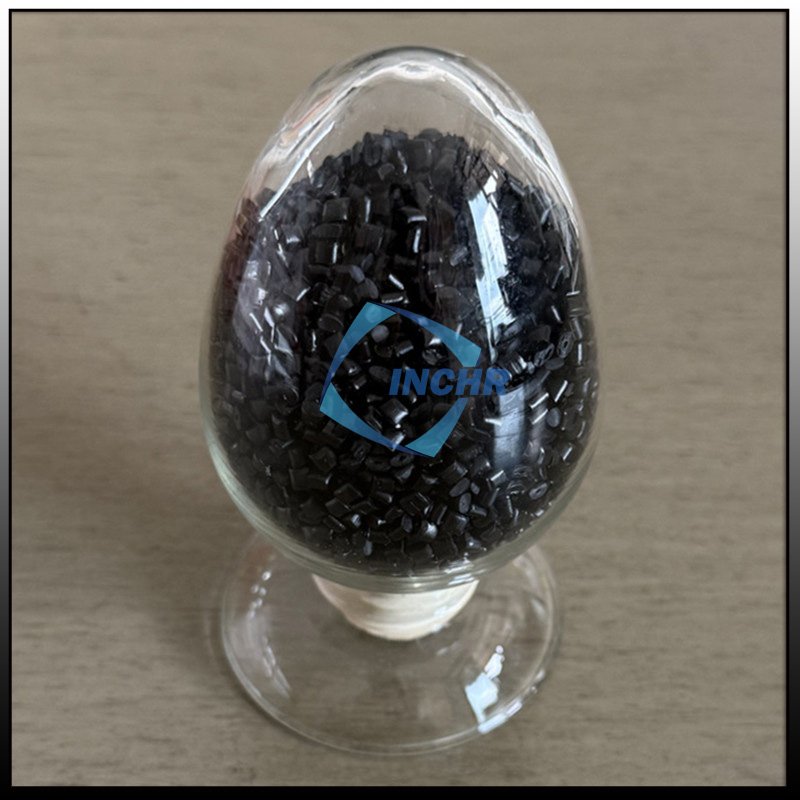

INCHR@Conductive POM compound stands out with its unique performance and has become the focus of attention of many industries. The conductive POM compound combines the excellent properties of polyoxymethylene (POM) with conductive function, is bringing new solutions to various fields with its incomparable advantages.

Excellent conductive performance, leading a new era of electronics | Product Catalog

Although traditional POM materials have excellent mechanical properties, they have natural shortcomings in the field of conductivity. The conductive POM compound has successfully broken this limitation by adding conductive fillers such as carbon nanotubes, carbon fibers, and metal powders. Its conductive performance is extremely excellent, which can quickly conduct away static electricity and effectively prevent the harm caused by static electricity accumulation. In the field of electronics and electrical appliances, conductive POM can be used to manufacture electronic component packaging, circuit board shielding materials, etc. For example, in precision electronic equipment, electronic components are sensitive to static electricity, and the accumulation of static electricity may cause component damage and affect the normal operation of the equipment. The application of a conductive POM compound can be like a solid “static protection wall” to conduct static electricity in time, protect the safety of electronic components, and ensure the stable and reliable operation of electronic equipment. At the same time, it also performs very well in electromagnetic shielding, which can effectively shield external electromagnetic interference and ensure the pure transmission of electronic signals, providing a solid material foundation for fields such as 5G communications and the Internet of Things that have extremely high requirements for signal quality.

Strong mechanical properties to cope with complex working conditions

POM itself is known for its high strength, high hardness, and excellent rigidity, and is widely used in occasions that need to withstand large mechanical stress. INCHR@Conductive POM compound not only gives the material conductive properties but also maintains excellent mechanical properties. It has good wear resistance and can maintain structural integrity and functionality for a long time even in high friction and high wear environments. In the automotive industry, the working environment of the engine compartment, chassis, and other parts of the car is complex, and the components not only have to withstand large mechanical loads but also may face harsh conditions such as high temperature and oil pollution. Sensors, connectors, and other components in automotive electronic systems made of conductive POM compounds can not only ensure the stable transmission of signals but also rely on their excellent mechanical properties to operate stably under complex working conditions, greatly improving the service life and reliability of automotive parts. In addition, in the field of aerospace, aircraft will be subjected to various mechanical loads during flight. The high strength and rigidity of conductive POM composites enable them to meet the strict requirements of aerospace equipment for high performance and reliability of structural materials and help the development of aerospace technology.

Convenient processing, accelerating the innovation process

INCHR@Conductive POM composites can be quickly and efficiently processed into various complex-shaped products through a variety of mature processing technologies such as injection molding and extrusion molding. This advantage brings great flexibility to product design and manufacturing, whether it is small and precise electronic components or large and complex mechanical structural parts, it can be easily realized. For product R&D companies, the ability to quickly transform design concepts into actual products greatly shortens the product R&D and production cycle and improves the market competitiveness of companies. At the same time, good molding and processing performance also means that the difficulty and cost of processing can be reduced, and the scrap rate caused by processing difficulties can be reduced, further enhancing the economic value of conductive POM in practical applications.

Good chemical stability, broadening the scope of application

POM itself has excellent chemical stability, is almost insoluble in common organic solvents, and has a good tolerance to many chemicals. The conductive POM inherit this characteristic, can still maintain stable performance in different chemical environments, and are not easily corroded by corrosion and chemical substances. POM has good tolerance to organic solvents such as hydrocarbons, esters, ethers, and ketones. At room temperature, these solvents will not cause significant swelling or dissolution of POM, and their mechanical properties and dimensional stability can be maintained well. For example, in the automotive fuel system, POM parts can be in contact with gasoline, diesel, and other fuels for a long time without being corroded or damaged, and can also prevent static electricity from adsorbing dust and impurities.

INCHR@Conductive POM compound has shown incomparable absolute advantages with its excellent conductivity, strong mechanical properties, convenient molding and processing, and good chemical stability. With the continuous development of materials science and the increasing maturity of application technology, conductive POM compounds will surely play an important role in more fields, injecting strong impetus into promoting technological progress and innovative development in various industries, and opening a new chapter in material application.