Electrostatically Dissipative Polyether Ether Ketone (ESD PEEK) is a high-performance thermoplastic renowned for its exceptional thermal stability, mechanical strength, and electrical properties. This article delves into the temperature resistance of ESD PEEK, analyzing its performance across an ultra-wide range of -200°C to 260°C, and explores its critical role in demanding industrial applications.

Understanding ESD PEEK

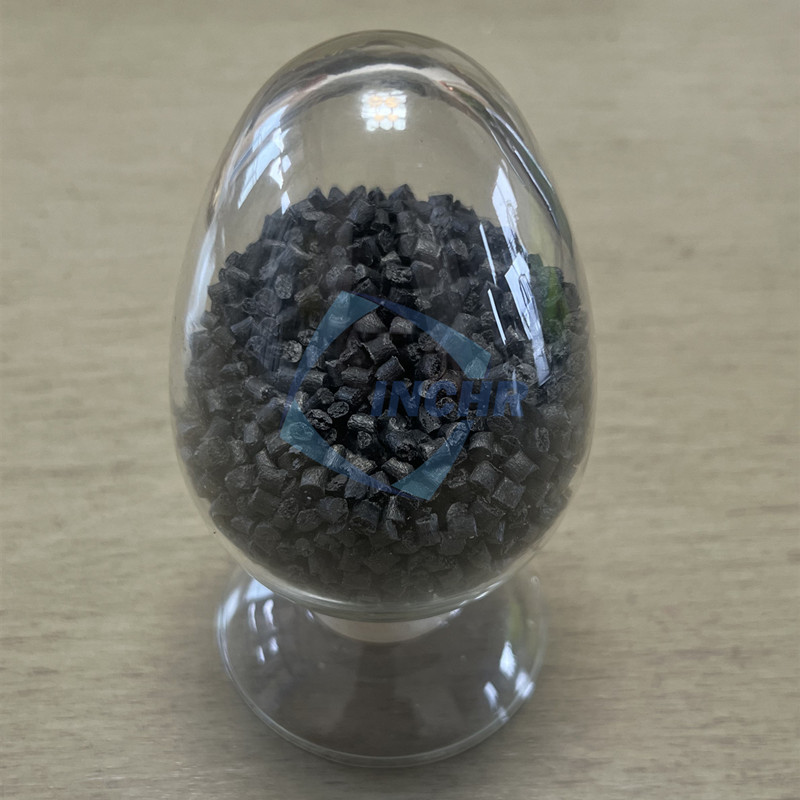

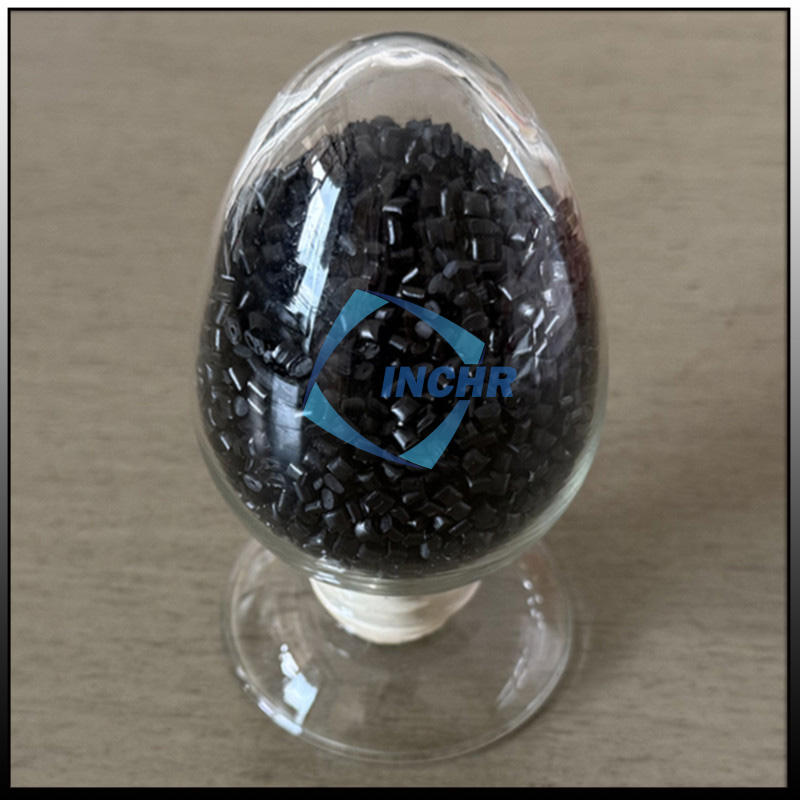

ESD PEEK is a carbon-filled variant of PEEK engineered to provide electrostatic dissipation, preventing damage to sensitive electronic components. Unlike standard polymers, it retains its properties under extreme thermal, chemical, and mechanical stress, making it ideal for aerospace, semiconductor, and automotive industries.

Low-Temperature Performance (-200°C)

At cryogenic temperatures as low as -200°C, It demonstrates remarkable toughness and dimensional stability. It resists embrittlement, a common failure mode in polymers, ensuring reliability in applications like space exploration and cryogenic storage. Its low thermal contraction coefficient minimizes stress in tightly toleranced assemblies.

High-Temperature Performance (up to 260°C)

It excels in high-temperature environments, maintaining structural integrity and mechanical properties at continuous service temperatures up to 260°C. It resists thermal degradation, creep, and chemical attack, outperforming metals and conventional plastics. This makes it suitable for semiconductor manufacturing, where wafer handling components face repeated exposure to elevated temperatures.

Thermal Stability Mechanisms

The inherent stability of PEEK’s molecular structure, combined with carbon additives, enables ESD PEEK to withstand thermal cycling without cracking or warping. Its glass transition temperature (~143°C) and melting point (~343°C) further contribute to its high-temperature resilience.

Applications in Extreme Environments

ESD PEEK is used in:

Semiconductor equipment: Wafer carriers and robotic end-effectors.

Aerospace: Components for satellites and cryogenic fuel systems.

Automotive: Sensors and connectors in high-temperature engine compartments.

Comparative Advantages

Compared to metals, It offers weight reduction, corrosion resistance, and inherent lubrication. Versus other plastics, it provides superior thermal and electrical properties.

Conclusion

ESD PEEK’s ability to perform reliably from -200°C to 260°C makes it a material of choice for extreme-environment applications. Its combination of thermal resilience, mechanical strength, and ESD protection ensures longevity and safety in critical industries.

For more details on ESD PEEK properties, refer to NASA’s material guidelines.