Understanding ESD PEEK Specifications: A High-Performance Polymer

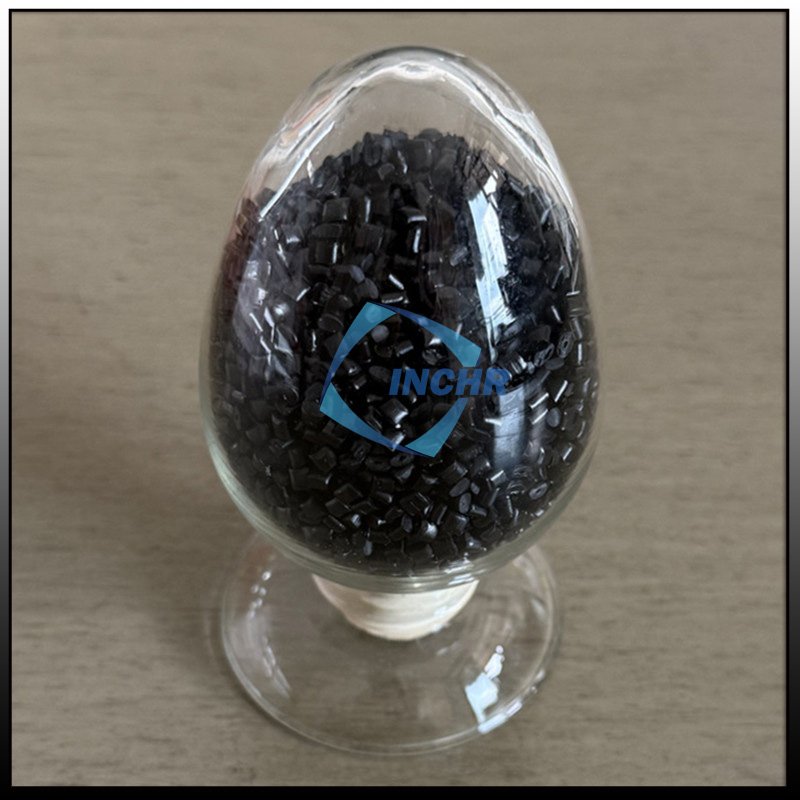

Electrostatically Dissipative Polyether Ether Ketone (ESD PEEK) is a premier high-performance thermoplastic engineered for environments where controlling electrostatic discharge (ESD) is critical. Unlike standard PEEK, which is an excellent electrical insulator, ESD PEEK is formulated with conductive fillers like carbon fibers or nanotubes to provide a safe, controlled path for static electricity dissipation, protecting sensitive electronic components from damage.

This article delves into the key specifications that make ESD PEEK an indispensable material in sectors like semiconductor manufacturing, aerospace, electronics, and medical device production.

Key Specifications and Properties

The value of ESD PEEK lies in its combination of inherent PEEK properties with tailored electrostatic performance.

1. Electrostatic Discharge (ESD) Properties:

The primary specification for ESD PEEK is its surface resistivity, typically measured in ohms per square (Ω/sq). Standard ESD grades exhibit a surface resistivity in the range of 10^6 to 10^9 Ω/sq. This range is ideal as it sits between conductive (less than 10^6 Ω/sq) and insulating (greater than 10^12 Ω/sq) materials, allowing charge to drain slowly and safely without a sudden discharge.

2. Mechanical Properties:

It retains the exceptional mechanical strength of virgin PEEK. Key specifications include:

High Tensile and Flexural Strength: It maintains robust strength and stiffness, even at elevated temperatures.

Excellent Wear Resistance: Its inherent lubricity and hardness make it suitable for moving parts like gears and bearings in cleanrooms.

Dimensional Stability: It offers low moisture absorption and a high glass transition temperature (~143°C), ensuring parts retain their shape and size under stress and heat.

3. Thermal Properties:

ESD PEEK performs reliably in high-temperature environments.

Continuous Use Temperature: It can operate continuously at temperatures up to 250°C (482°F).

Excellent Flame Resistance: It is inherently flame-retardant, typically achieving a V-0 rating in the UL94 vertical burning test.

4. Chemical Resistance:

Like standard PEEK, ESD grades exhibit outstanding resistance to a wide range of chemicals, including acids, bases, hydrocarbons, and solvents. This makes it suitable for harsh processing environments, including those requiring aggressive cleaning agents.

5. Cleanroom Compatibility:

It is renowned for its low outgassing and minimal particulate generation, which is a mandatory requirement in semiconductor fabrication and pharmaceutical processing to prevent contamination.

Applications and Industries

The unique specifications of ESD PEEK make it ideal for:

Wafer Carriers and Handling Equipment: [Internal link to /materials/peek-semiconductor-applications] in semiconductor plants.

Test Sockets and Burn-In Sockets: For delicate integrated circuit (IC) testing.

Aerospace Components: Where ESD protection and weight reduction are vital.

Medical Device Trays and Tools: Used in sensitive electronic surgical equipment.

Robotic End-Effectors: Used in automated electronics assembly lines.

Conclusion

By effectively mitigating ESD risks while performing under extreme conditions, it ensures the reliability and longevity of sensitive electronic components and the equipment that handles them.

For more detailed data sheets on specific ESD PEEK grades, refer to authoritative sources.