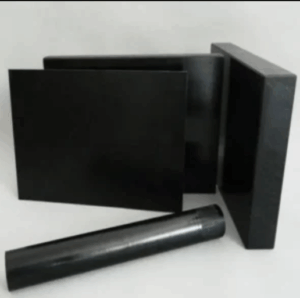

Electrostatic Dissipative (ESD) Polyether Ether Ketone (PEEK) is a high-performance thermoplastic engineered to combine the exceptional inherent properties of PEEK with reliable electrostatic dissipation. This makes it an ideal material for industries where static electricity can damage sensitive components or cause safety hazards, such as electronics, semiconductor manufacturing, and aerospace. This article provides a comprehensive technical overview of ESD PEEK’s key properties and applications.

What is ESD PEEK?

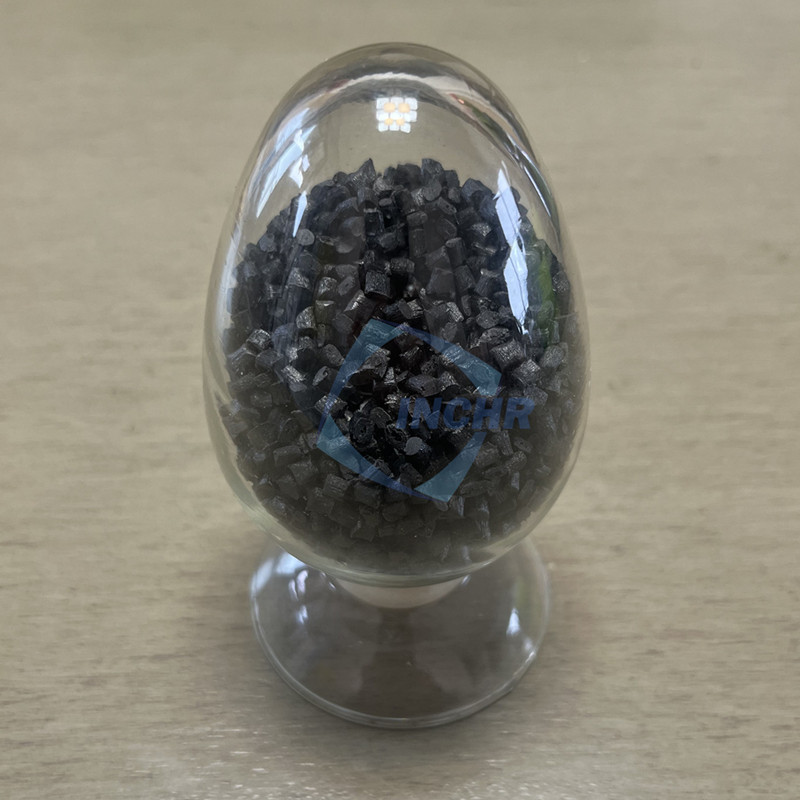

It is a modified version that incorporates conductive fillers, such as carbon nanotubes or carbon fibers. These additives create a continuous path for static charges to dissipate safely, preventing the buildup that could lead to electrostatic discharge—without compromising the base material’s renowned performance.

Key Technical Properties of ESD PEEK

Electrostatic Dissipation (ESD)

It typically offers a surface resistance in the range of 10^6 to 10^9 ohms, placing it perfectly within the safe dissipative range. This protects sensitive electronic components from damage during manufacturing, handling, and use.Outstanding Mechanical Strength

Like its pristine counterpart, It retains excellent mechanical properties. It boasts high tensile strength, stiffness, and outstanding resistance to fatigue and wear. This makes it suitable for demanding applications like robotic end-effectors, wafer handlers, and jigs that require both precision and durability.High Thermal Stability

ESD PEEK performs reliably in high-temperature environments. It has a continuous service temperature of up to 250°C (482°F), making it ideal for processes involving soldering, autoclaving, or other high-heat scenarios where other ESD plastics might fail.Excellent Chemical Resistance

This material is highly resistant to a wide range of chemicals, including acids, bases, hydrocarbons, and solvents. This allows components made from ESD PEEK to be cleaned with aggressive solvents without degrading their structural integrity or ESD performance.Low Outgassing and Cleanroom Compatibility

ESD PEEK exhibits very low levels of outgassing, which is critical in vacuum environments and cleanrooms. It prevents particulate contamination that could ruin semiconductor wafers or optical instruments, making it a staple in the electronics and aerospace sectors.

Applications of ESD PEEK

The unique combination of properties makes ESD PEEK the material of choice for:

Semiconductor manufacturing equipment (wafer carriers, test sockets)

Automation and robotics (grippers, guides)

Medical device components

Aerospace interior components and fixtures

Jigs and fixtures for electronics assembly

Conclusion

ESD PEEK stands as a pinnacle of material engineering, offering an unmatched blend of electrostatic dissipation, mechanical robustness, and thermal resistance. For engineers and designers working in high-tech, sensitive environments, specifying it is a reliable strategy to enhance product safety, longevity, and performance.

For more information on our range of high-performance PEEK materials, contact our experts today.