ESD PEEK Material: Antistatic Properties, Applications, and Selection Guide

In demanding environments where static discharge is a critical threat, standard engineering plastics often fall short. Enter ESD PEEK (ElectroStatic Dissipative Polyetheretherketone), a high-performance polymer engineered to combine PEEK’s exceptional properties with vital antistatic protection. This guide explores its properties, key applications, and selection criteria.

Understanding the Antistatic Need

Static electricity poses significant risks:

Component Damage: Sensitive electronics (chips, PCBs) can be destroyed by ElectroStatic Discharge (ESD).

Ignition Hazard: Sparks can ignite flammable gases, dust, or solvents.

Process Disruption: Static attracts dust and contaminants, disrupting precision manufacturing or cleanroom processes.

Operator Discomfort: Static shocks affect worker safety and morale.

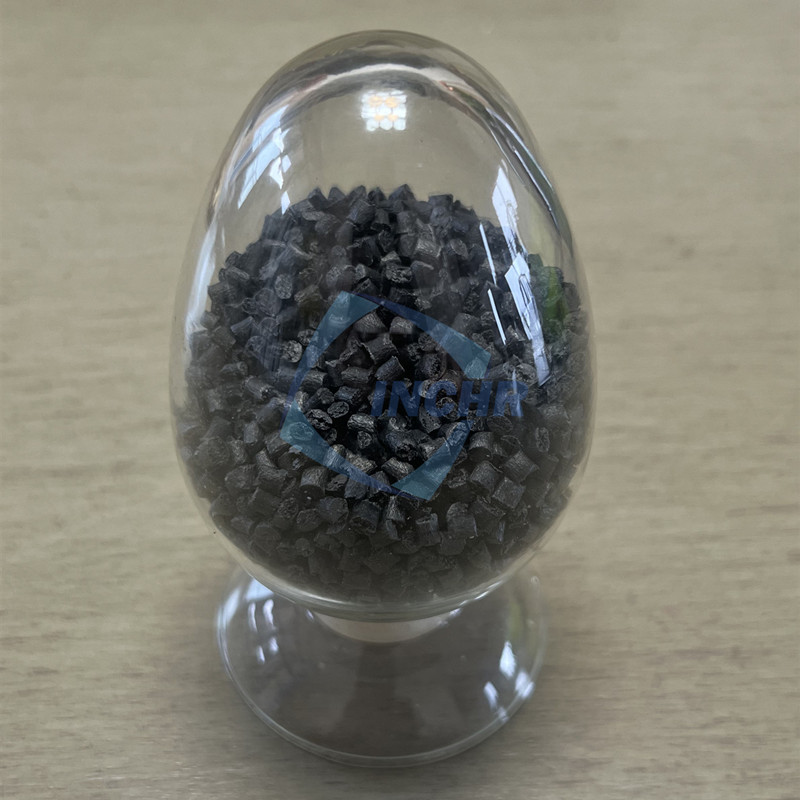

Standard PEEK, while incredibly robust chemically, thermally, and mechanically, is an excellent electrical insulator. This inherent insulation allows static charges to build up dangerously. ESD PEEK solves this by incorporating specialized additives (like carbon nanotubes, carbon fibers, or organic antistats) that create controlled pathways for static charge to dissipate safely to ground.

Controlled Antistatic Performance: The defining characteristic. ESD PEEK exhibits a surface resistivity typically within the 10⁶ to 10⁹ Ω/sq range, effectively preventing static charge accumulation and enabling safe dissipation.

Retained High-Temperature Performance: Inherits PEEK’s outstanding thermal stability, with continuous use temperatures often exceeding 250°C (482°F) and short-term peaks much higher.

Superior Mechanical Strength & Stiffness: Maintains excellent tensile strength, compressive strength, and dimensional stability under load, even at elevated temperatures.

Exceptional Chemical Resistance: Highly resistant to a vast array of chemicals, solvents, and hydrolysis, making it suitable for harsh processing environments.

Low Outgassing & High Purity: Critical for vacuum applications and cleanrooms, minimizing contamination risks. Meets stringent standards like NASA low outgassing.

Wear Resistance: Offers good resistance to friction and wear, beneficial for moving parts.

Inherent Flame Retardancy: Like standard PEEK, it achieves excellent flame ratings (e.g., UL94 V-0) without added halogenated flame retardants.

Primary Applications of ESD PEEK

ESD PEEK shines in industries where static control is paramount alongside demanding physical conditions:

Semiconductor Manufacturing: Wafer handling components (carriers, cassettes, robots arms), test sockets, probe cards, vacuum chamber parts.

Electronics Production & Testing: Fixtures, jigs, test equipment housings, conveyor components near sensitive PCBs.

Medical Device Manufacturing: Components for assembling sensitive electronic medical devices, cleanroom tooling, surgical instrument parts requiring sterilization.

Industrial Automation: Robot end-effectors, grippers, and guides used in electronics assembly or near flammable substances.

Aerospace & Defense: Components for avionics housings, satellite instrumentation, fuel system parts requiring static control.

Chemical Processing: Valves, pump components, seals, and liners in environments with flammable solvents or powders.

Selection Guide: Key Considerations

Choosing the right ESD PEEK grade is crucial:

Required Surface/Volume Resistivity Level: Determine the specific ESD range needed (e.g., 10⁶-10⁸ Ω/sq vs. 10⁸-10¹⁰ Ω/sq). Consult relevant standards (e.g., ANSI/ESD S20.20).

Mechanical Load & Stress: Consider tensile, compressive, and impact requirements. Carbon fiber-reinforced ESD PEEK offers higher stiffness and strength.

Operating Temperature: Ensure the grade can withstand peak and continuous service temperatures.

Chemical Exposure: Verify compatibility with specific chemicals, solvents, or cleaning agents used.

Wear & Friction Needs: If subject to sliding contact, consider grades optimized for wear resistance.

Regulatory Compliance: Check for necessary certifications (FDA, USP Class VI, UL 94, NASA outgassing).

Machinability & Fabrication: Some ESD additives can affect machining ease. Discuss requirements with your supplier or processor.

Cost vs. Performance: ESD PEEK commands a premium over standard PEEK or lower-performance ESD plastics. Ensure the superior properties justify the investment.

Conclusion

ESD PEEK material is an indispensable solution where uncompromising static control intersects with extreme thermal, chemical, and mechanical demands. Its unique blend of antistatic properties and inherent PEEK performance makes it the material of choice for mission-critical applications in semiconductors, electronics, medical tech, and beyond. By carefully considering the required resistivity level, environmental conditions, and mechanical needs outlined in this guide, engineers can confidently select the optimal ESD PEEK grade to enhance safety, reliability, and product longevity.