Beyond Strength and Heat: The Critical Role of ESD PEEK

In the demanding worlds of semiconductor manufacturing, aerospace, and medical device production, material selection is everything. Components must withstand extreme temperatures, aggressive chemicals, and constant mechanical stress. But there’s another, invisible threat: electrostatic discharge (ESD). A single spark can ruin a delicate electronic component or ignite a volatile atmosphere. This is where advanced engineering polymers step in, with Esd Peek one offering a particularly unique set of properties.

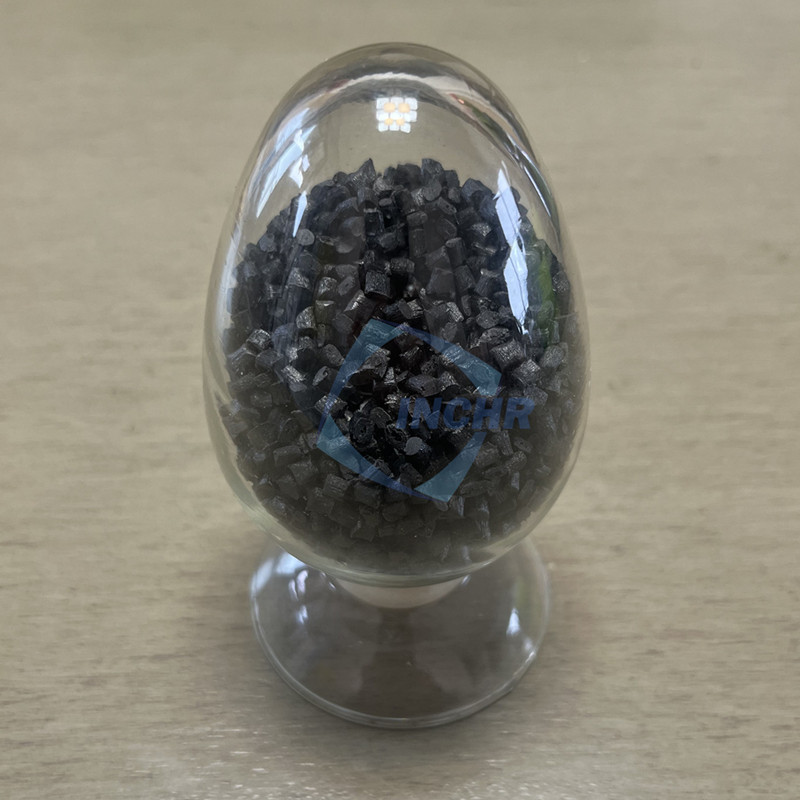

While standard PEEK (Polyether Ether Ketone) is renowned as a high-performance thermoplastic, its inherent electrical insulation is a liability in sensitive environments. A specialized variant has been developed to solve this exact problem, combining the legendary benefits of the base polymer with crucial electrostatic protection.

Caption: Preventing microscopic damage from ESD PEEK is critical in semiconductor fabrication.

What Makes This Material So Special?

This engineered compound retains all the exceptional qualities that make PEEK a top choice for engineers:

Incredible Mechanical Strength: It maintains high tensile strength and stiffness, even at elevated temperatures, rivaling many metals.

Exceptional Thermal Resistance: It can operate continuously at temperatures up to 250°C (482°F), making it ideal for autoclaving and high-heat processes.

Outstanding Chemical Resistance: It resists a wide range of chemicals, including acids, bases, hydrocarbons, and solvents, ensuring long-term durability.

Inherent Purity & Low Outgassing: These properties make it perfect for vacuum environments and cleanrooms, as it won’t contaminate sensitive processes.

The critical enhancement is the incorporation of specialized additives that provide permanent and reliable static control. This allows the material to safely dissipate electrostatic charges, protecting both products and personnel without the dust-attracting issues of conductive materials.

Esd Peek Key Applications Across Industries

The combination of inherent robustness and ESD protection opens doors to critical applications:

Semiconductor & Electronics Manufacturing: Used for wafer carriers, test sockets, handling tools, and robotic end-effectors. These components must be strong enough for automation, clean enough for the fab, and safe enough to prevent damaging microchips.

Aerospace & Defense: Ideal for fuel system components, sensor housings, and interior parts where weight reduction, chemical resistance, and preventing sparks in flammable environments are paramount.

Medical Device Manufacturing: Used in production equipment for assembling sensitive medical electronics. Its ability to be repeatedly sterilized without degrading is a major advantage.

Industrial Automation: In automated guided vehicles (AGVs), robotic arms, and assembly fixtures, where friction can generate damaging static charges on sensitive products.

Caption: Precision-machined components made from static-dissipative polymers ensure safety and reliability.

Conclusion

In high-stakes industries, compromise is not an option. This specialized, static-dissipative version of PEEK delivers the perfect synergy of mechanical toughness, thermal stability, and essential electrostatic protection. It is a material engineered not just for performance, but for absolute reliability where failure is not an option. When your application demands the very best in static control and material properties, it stands as the unequivocal choice.

For a deeper dive into material selection for ESD-sensitive environments, check out our Ultimate Guide to E-Safe Plastics.