In our increasingly electrified and electronic world, efficiently managing electrical currents and static charge is fundamental. Electrically conductive compounds are the engineered materials that play this vital role across countless industries, offering solutions where traditional metals or simple plastics fall short.

What is a Electrically conductive compounds?

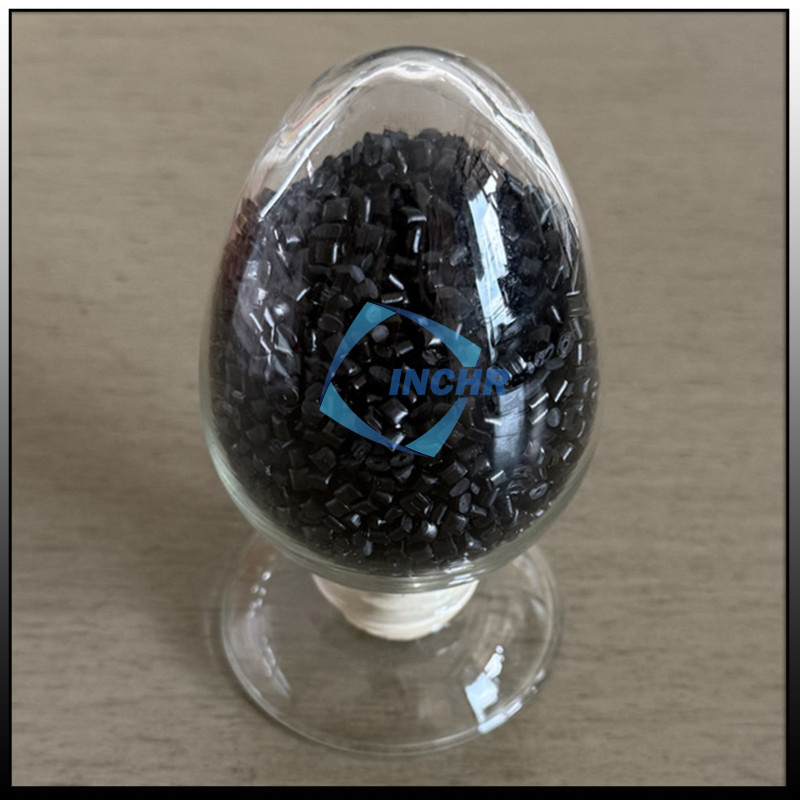

A conductive compound is a specially formulated blend where conductive particles or fibers (known as the filler) are uniformly dispersed within a non-conductive base material (called the matrix, typically a polymer resin like plastic, rubber, or coating). The base polymer provides essential properties like structural integrity, flexibility, moldability, chemical resistance, and lightweight design, while the filler imparts the crucial electrical functionality.

The Core Principle: Achieving Connectivity via Percolation

The fundamental principle enabling a Electrically conductive compound’s function is the formation of a percolation network:

Insulating Matrix: The base polymer (e.g., PP, PE, PVC, Silicone, Epoxy, Nylon) is inherently non-conductive, acting as an electrical insulator.

Conductive Filler: Particles or fibers with high electrical conductivity are added. Common types include:

Carbon Black: Most common, cost-effective, offers moderate conductivity (ideal for static dissipation).

Metallic Powders: Nickel, Silver, Copper (often coated to prevent oxidation) – provide high conductivity.

Carbon Fibers: Offer good conductivity and significant mechanical reinforcement.

Specialty Fillers: Graphite, coated glass beads, inherently conductive polymers (ICPs).

Percolation Threshold: As the amount of filler added increases, a critical point is reached – the percolation threshold. At this loading, the filler particles physically touch or come close enough for electrons to “jump” (quantum tunneling) between them. This creates continuous, interconnected pathways (a network) through the material.

Transformation: Once the percolation network forms, the entire compound transforms from an insulator into a conductor or static dissipator. The level of conductivity depends heavily on the filler type, shape, loading level (above the threshold), and distribution.

Key Properties of Electrically conductive compounds

These materials deliver a unique synergy of properties derived from both the polymer matrix and the conductive filler:

Electrical Conductivity: Ranges widely:

Anti-Static (ESD): Surface Resistivity ~10⁹ – 10¹² ohms/sq (prevents static build-up/sparks).

Static Dissipative (SD): Surface Resistivity ~10⁶ – 10⁹ ohms/sq (safely bleeds charge).

Conductive: Surface Resistivity <10⁵ ohms/sq or Volume Resistivity <100 ohm-cm (often <1 ohm-cm) (provides EMI shielding or electrical pathways).

Retained Polymer Properties: Maintains the base polymer’s core benefits: lightweight, corrosion resistance, design flexibility (suitable for injection molding, extrusion, coating), chemical resistance, and often colorability (especially with carbon fiber or nickel fillers).

Mechanical Properties: Can be tailored based on filler choice:

Carbon Fibers significantly enhance strength and stiffness.

Metallic Powders increase density and thermal conductivity.

Carbon Black can sometimes reduce impact strength or elongation.

Processability: Designed to be compatible with standard plastics and rubber manufacturing techniques (molding, extrusion).

Durability & Consistency: Provides inherent, long-lasting conductivity throughout the part’s lifetime, unlike topical coatings that can scratch, wear off, or degrade.

Wide-Ranging Industry Applications

Electrically conductive compounds solve critical electrical management challenges across diverse sectors:

Electronics & Semiconductors (ESD/SD Protection):

Static-Safe Packaging: Trays, tubes, boxes, bags to prevent electrostatic discharge (ESD) damage to sensitive components during shipping, handling, and storage.

ESD-Safe Workstations: Flooring tiles, mats, chairs, tool handles, soldering iron tips, wrist strap connectors.

Device Housings & Components: Internal parts for computers, phones, printers requiring EMI/RFI shielding, grounding paths, or static control.

Connectors & Sockets.

Automotive & Electric Vehicles (EVs):

Fuel Systems: Fuel lines, filler necks, pump components to prevent static sparks near flammable vapors.

Battery Systems (Critical for EVs): Cell holders/spacers, busbar insulators, module housings, connectors requiring electrical isolation and conductivity for cell voltage sensing, temperature monitoring, or grounding. Thermal interface materials (TIMs).

Sensors & Connectors: Housings needing EMI shielding or electrical grounding.

Heated Components: Elements for seats, mirrors, steering wheels, battery warming.

EMI Shielding: For sensitive electronics and increasing electrification.

Industrial & Process Manufacturing:

Explosion Prevention: Hoppers, liners, pipes, fittings, filters for handling flammable powders, granules, or liquids (e.g., plastics, chemicals, pharmaceuticals).

ESD-Safe Conveyor Belts: For electronics assembly, munitions, painting lines.

Grounding Straps & Components.

Process Equipment: Sensors, chutes, machinery parts where static causes issues (clogging, contamination).

Aerospace:

Lightweight EMI/RFI Shielding for avionics housings and components.

Fuel System Components (static control).

De-Icing System Components.

Composite Part Tooling (static dissipation).

Medical Devices:

EMI Shielding for sensitive diagnostic equipment housings (MRI, monitors).

ESD-Safe Equipment: Wheels, carts, trays used in electronics manufacturing or labs within medical facilities.

Specialized Sensors & Electrodes.

Surgical tool components.

Energy (Oil & Gas, Renewables):

Subsea Power Cables: Semiconductive layers critical for HV AC and DC cable construction (smoothing the electric field).

Explosive Environment Components: Pipes, valves, fittings in potentially flammable atmospheres (ATEX/IECEx zones).

Solar Panel Components: Junction boxes, connectors, backsheets requiring conductivity.

Wind Turbine Components: Blades (lightning protection), generators (shielding).

Conclusion: The Engineered Electrical Solution

Electrically conductive compounds are sophisticated, engineered materials designed to solve complex electrical challenges. By intelligently blending conductive fillers within versatile polymer matrices, they deliver essential electrical properties – static dissipation (ESD/SD), EMI shielding, or bulk conductivity – while retaining the processing advantages (design freedom, lightweight) and performance benefits (corrosion resistance, chemical resistance) of plastics and rubbers.

From protecting delicate microchips and enabling safe electric vehicle batteries to ensuring explosion safety in industrial plants and efficient power transmission under the sea, these versatile compounds are indispensable enablers of modern technology across virtually every industrial sector. Their development continues to evolve rapidly, driven by demands for higher conductivity, enhanced multifunctionality (e.g., thermal + electrical), improved mechanical properties, and more sustainable formulations, constantly pushing the boundaries of application possibilities.