In the rapidly evolving world of electronics and telecommunications, the demand for materials that combine conductivity, durability, and flexibility is higher than ever. Conductive PVC compounds have emerged as a game-changing solution, offering high conductivity while retaining the proven benefits of traditional PVC. These advanced materials are transforming applications in cables, electronic housings, anti-static flooring, and electromagnetic interference (EMI) shielding.

What Are Conductive PVC Compounds?

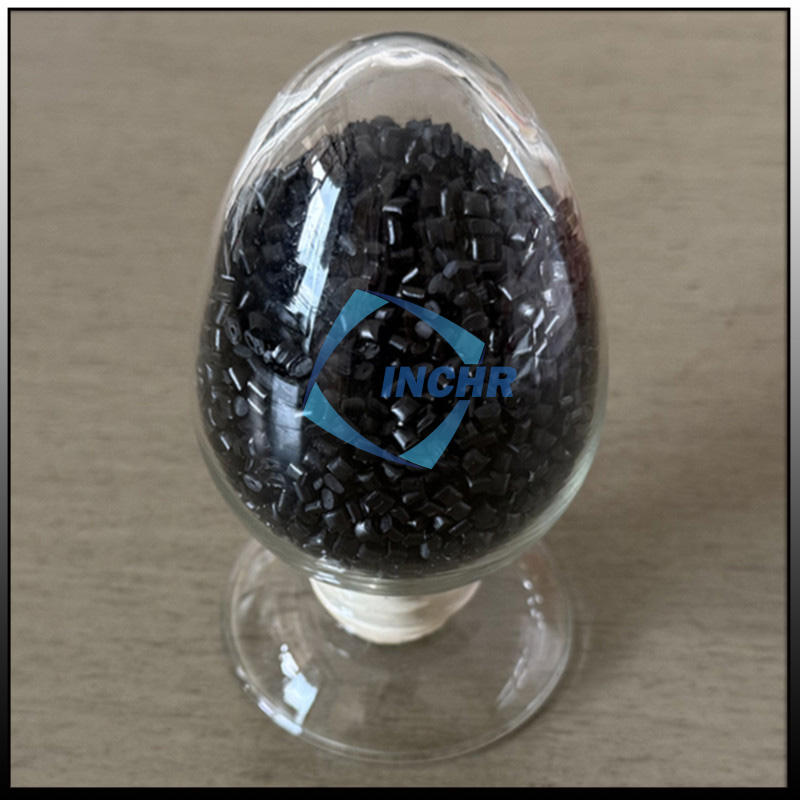

Polyvinyl Chloride (PVC) is a widely used thermoplastic known for its cost-effectiveness, chemical resistance, and mechanical strength. Conductive PVC compounds are engineered by incorporating conductive fillers—such as carbon black, carbon nanotubes, or metallic particles—into the PVC matrix. This blend imparts electrical conductivity to the otherwise insulating polymer, making it suitable for applications where static dissipation or electrical transmission is critical.

Key Applications

1. Cable Shielding

One of the primary uses of conductive PVC is in the sheathing and insulation of cables. These compounds provide excellent EMI and radio frequency interference (RFI) shielding, which is essential for maintaining signal integrity in data transmission cables, power cables, and communication lines. By preventing external electromagnetic disturbances, conductive PVC ensures reliable performance in sensitive environments.

Read more about The Application Of Conductive PVC Compounds In Compression-Formed Antistatic Flooring

2. Electronics Housings

Electronic devices require protection from static electricity, which can damage sensitive components. Conductive PVC is used in casings for devices such as routers, sensors, and industrial control systems to dissipate electrostatic charges safely. Its moldability allows for complex designs, making it ideal for custom electronic enclosures.

3. Anti-Static Flooring and Mats

In environments like server rooms, manufacturing facilities, and laboratories, static electricity poses a significant risk. Conductive PVC flooring and mats provide a durable, easy-to-clean surface that safely grounds static charges, protecting both equipment and personnel.

4. Specialized Industrial Components

From conveyor belts to automotive parts, conductive PVC compounds are used in components where static buildup could lead to fires, explosions, or operational failures. Their resistance to oils, chemicals, and abrasion makes them suitable for harsh industrial settings.

Advantages of Conductive PVC Compounds

High Conductivity: Achieve surface resistivity as low as 10^3 Ω/sq, effectively dissipating static charges.

Flexibility and Durability: Unlike rigid metal shields, conductive PVC maintains flexibility, making it easier to install in tight spaces while resisting wear and tear.

Cost-Effectiveness: Offers a more affordable alternative to metal-based shielding or specialty polymers.

Customizability: Manufacturers can adjust conductivity levels, color, and physical properties to meet specific requirements.

Future Trends and Innovations

Research is focused on enhancing conductivity while reducing filler content to maintain mechanical properties. Nanotechnology, particularly graphene and carbon nanotube integration, is pushing the boundaries of what conductive polymers can achieve. As the Internet of Things (IoT) and 5G networks expand, the need for advanced materials like conductive PVC will only grow.

Conclusion

Conductive PVC compounds represent a critical innovation at the intersection of polymer science and electronics. By offering a unique combination of conductivity, flexibility, and cost-efficiency, they address some of the most pressing challenges in modern technology. For engineers and designers, these materials open new possibilities for safer, more efficient, and more reliable electronic and cable applications.