In today’s tech-driven industries—from electronics manufacturing to automotive engineering and medical device production—conductive compounds have become indispensable materials. Unlike ordinary polymers, these specialized materials blend base resins with conductive fillers to deliver electrical conductivity while retaining mechanical flexibility. But what exactly makes a high-quality conductive compound stand out? Let’s break down the core product characteristics that define its performance, reliability, and suitability for diverse applications.

1. Electrical Conductivity: The Core Functional Trait

At the heart of any conductive compound is its ability to transmit electricity—and not all conductivity is created equal. This characteristic is measured by two key metrics: volume resistivity (ohms-cm, Ω·cm) and surface resistivity (ohms per square, Ω/□).

- Fillers Determine Conductivity Levels: The type and concentration of conductive fillers directly impact performance. Carbon-based fillers (e.g., carbon black, graphene, carbon nanotubes) are cost-effective for low-to-moderate conductivity needs (e.g., antistatic packaging, where resistivity of 10⁶–10¹¹ Ω·cm suffices). For high-conductivity requirements—such as circuit board components or EV battery connectors—metal fillers (e.g., silver, copper, nickel) deliver resistivity as low as 10⁻³ Ω·cm.

- Uniformity Matters: Top-tier compounds ensure consistent filler dispersion. Uneven distribution leads to “hot spots” (areas of high resistance) or failure to meet conductivity specs—critical for applications like sensors, where erratic electrical flow can compromise data accuracy.

2. Mechanical Stability: Balancing Conductivity and Durability

Conductive compounds don’t just need to conduct electricity—they must also withstand the physical demands of their end-use environment. Poor mechanical properties can render a compound useless, even if its conductivity is exceptional.

- Tensile Strength & Flexibility: Base resins (e.g., polyethylene, polypropylene, silicone) influence flexibility. For example, silicone-based conductive compounds retain elasticity at extreme temperatures, making them ideal for automotive door seals (where they prevent static buildup and resist wear from vibration). In contrast, rigid compounds (e.g., filled with glass fibers) offer high tensile strength for structural parts like electrical enclosures.

- Abrasion & Impact Resistance: Industrial settings often involve friction or mechanical stress. Compounds with reinforced fillers (e.g., carbon fiber + carbon black) maintain conductivity even after repeated abrasion—essential for conveyor belts in electronics factories, where static control is critical to avoid damaging sensitive chips.

3. Thermal & Chemical Resistance: Surviving Harsh Environments

Many applications expose conductive compounds to extreme temperatures, chemicals, or moisture—so environmental stability is non-negotiable.

- Temperature Tolerance: High-temperature compounds (e.g., those using PEEK or PPS resins) remain conductive and structurally intact from -40°C to 200°C, suitable for under-the-hood EV components (e.g., battery bus bars) or industrial ovens. Low-temperature-grade options (e.g., TPE-based) stay flexible at -60°C, making them ideal for aerospace wiring.

- Chemical Compatibility: Resistance to oils, solvents, and corrosive substances is key for medical and food packaging uses. For example, FDA-approved conductive compounds (with platinum-cured silicone or HDPE bases) resist sanitizing agents (e.g., ethanol, hydrogen peroxide) and don’t leach toxins—critical for medical device housings or food processing equipment.

4. Processability: Easy Integration into Manufacturing

Even the most high-performing compound fails if it’s hard to produce with standard equipment. Processability directly impacts production efficiency and cost.

- Moldability & Extrudability: Quality compounds flow smoothly in injection molding or extrusion machines, ensuring complex shapes (e.g., thin-walled sensor casings or long cable sheaths) are produced without filler clumping or surface defects. For 3D printing applications, low-melt-viscosity conductive compounds work with FDM or SLA printers to create custom conductive parts (e.g., prototype circuit boards).

- Fast Cure Times: In high-volume manufacturing (e.g., consumer electronics), compounds that cure quickly (e.g., UV-curable conductive resins) reduce cycle times, keeping production lines moving.

5. Safety & Compliance: Meeting Global Standards

With increasing regulatory scrutiny, compliance is a non-negotiable characteristic—especially for industries like medical, automotive, and electronics.

- RoHS & REACH Compliance: Leading compounds avoid restricted substances (e.g., lead, cadmium, phthalates) to meet EU RoHS and REACH standards, ensuring they can be sold in global markets.

- Antimicrobial & Flame Retardant Add-Ons: For high-risk environments (e.g., hospitals or data centers), compounds may include antimicrobial agents (to prevent bacteria growth on medical devices) or flame retardants (to meet UL94 V-0 standards for electrical enclosures, reducing fire risk).

6. Customizability: Tailored to Specific Needs

No two applications are identical—and the best conductive compounds can be customized to match unique requirements.

- Adjustable Conductivity: Suppliers can tweak filler ratios to hit exact resistivity targets (e.g., 10⁴ Ω·cm for EMI shielding vs. 10⁹ Ω·cm for antistatic flooring).

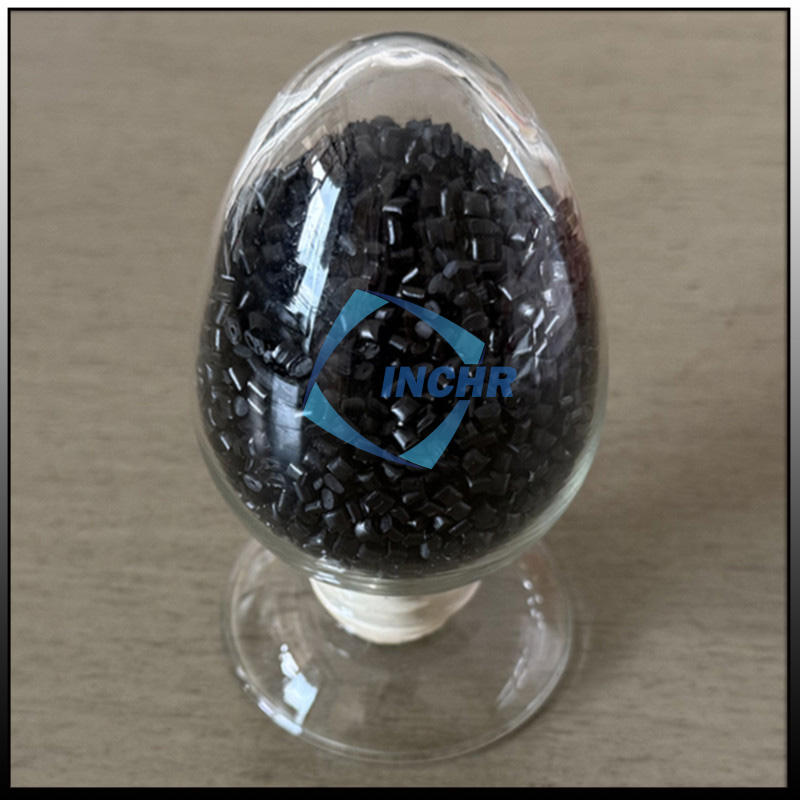

- Color & Texture: While carbon-based compounds are typically black, metal-filled options can be colored (e.g., silver-filled compounds for aesthetic medical devices) or textured (e.g., matte finishes for grip in industrial tools).

- Weight Optimization: For aerospace or wearable tech, lightweight fillers (e.g., hollow metal spheres) reduce compound density without sacrificing conductivity—critical for minimizing device weight.

How to Choose Based on These Characteristics

When selecting a conductive compound, start by prioritizing the traits that align with your application:

- For electronics: Prioritize high conductivity + RoHS compliance.

- For automotive: Focus on thermal resistance + impact strength.

- For medical: Prioritize FDA approval + chemical resistance.

By matching the compound’s characteristics to your end-use needs, you’ll ensure optimal performance, reduce downtime, and avoid costly redesigns.

Conductive compounds are more than just “conductive plastics”—their unique blend of functional, mechanical, and environmental traits makes them enablers of innovation across industries. As technology advances (e.g., faster EV charging, smaller medical sensors), expect these characteristics to evolve—with even higher conductivity, better durability, and more sustainable formulations leading the way.