In the intricate world of electronics, electric vehicles (EVs), aerospace, and industrial manufacturing, managing electrical flow is paramount. Static discharge can fry sensitive components, electromagnetic interference (EMI) can disrupt signals, and inefficient grounding poses safety risks. This is where conductive compound step in as essential engineering materials. This guide explores what they are, their types, key properties, and how to select the optimal one for your project.

What are Conductive Compound?

Conductive compounds are engineered materials created by blending insulating base polymers (like plastics, elastomers, or adhesives) with conductive fillers. These fillers create pathways within the material, allowing controlled electricity flow. The base polymer provides structural integrity, flexibility, chemical resistance, and ease of processing, while the conductive filler imparts the necessary electrical properties.

Why Use Conductive Compound? Key Applications

EMI/RFI Shielding: Protect sensitive electronics from external electromagnetic noise and prevent your device from emitting interfering signals (critical for medical devices, telecom, consumer electronics). Conductive enclosures and gaskets are common solutions.

ESD (Electrostatic Discharge) Protection: Safely dissipate static charges that could damage electronic components during handling or operation (essential in semiconductor manufacturing, cleanrooms, packaging).

Grounding: Provide reliable electrical paths to ground for safety and proper circuit function.

Electrodes & Current Collection: Used in batteries, fuel cells, and sensors where controlled current flow through a robust material is needed.

Heating Elements: Generate heat through electrical resistance (e.g., floor heating, defrosting elements).

Antistatic Surfaces: Prevent dust attraction and minimize spark risks in environments like chemical handling or film production.

Types of Conductive Compound

The performance and application largely depend on the conductive filler used:

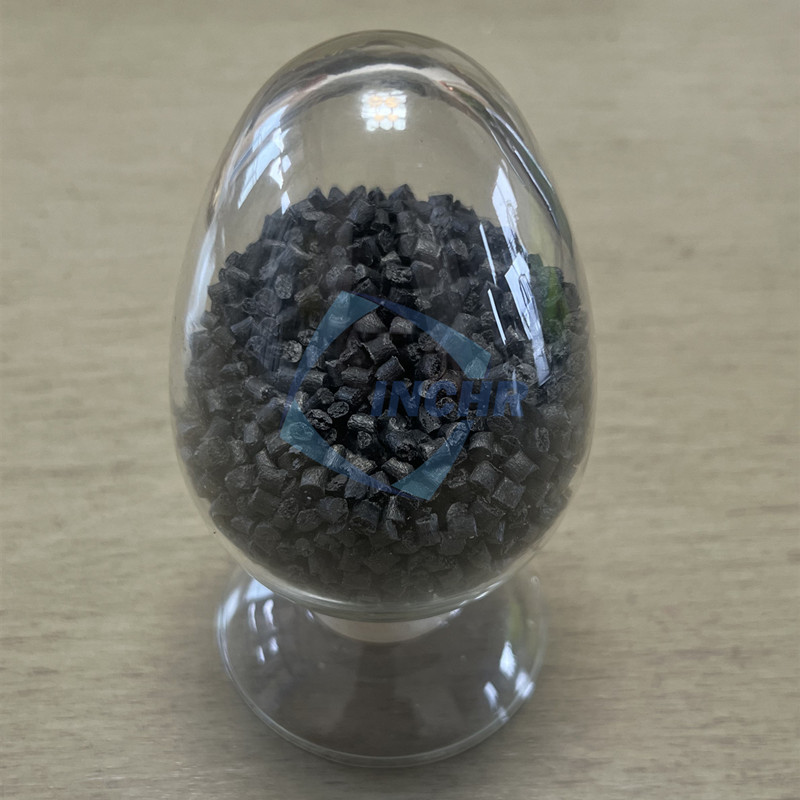

Carbon-Based Compounds:

Fillers: Carbon black, graphite, carbon fibers, graphene.

Conductivity Level: Low to Medium (typically > 10² Ω/sq surface resistivity). Ideal for ESD and antistatic applications.

Pros: Cost-effective, good processability, widely available, often black color.

Cons: Limited EMI shielding effectiveness (usually < 40 dB), potential for particle migration (“dirtying”), mechanical properties can be affected.

Metal-Filled Compounds:

Fillers: Silver (Ag), Nickel (Ni), Copper (Cu), Aluminum (Al), Stainless Steel flakes or fibers.

Conductivity Level: Medium to Very High (can achieve < 1 Ω/sq or even < 0.01 Ω/sq surface resistivity). Excellent for EMI shielding and grounding.

Pros: Highest conductivity, excellent EMI shielding (> 60 dB achievable), better mechanical strength retention than carbon-filled types (depending on filler).

Cons: Higher cost (especially Ag), higher density, potential for galvanic corrosion (Cu), oxidation (Cu), nickel allergies, processing challenges. Silver offers the best performance but is the most expensive.

Intrinsically Conductive Polymers (ICPs): (Less common as bulk compounds currently)

Materials: Polyaniline (PANI), Polypyrrole (PPy), PEDOT:PSS.

Conductivity Level: Variable, often comparable to carbon-filled.

Pros: Corrosion resistance, potentially lighter weight, design flexibility.

Cons: Higher cost, processing can be complex, stability/durability concerns in some environments, generally lower conductivity than metal-filled.

Key Properties to Consider When Selecting

Choosing the right conductive compound requires balancing multiple factors:

Electrical Performance:

Surface Resistivity (Ω/sq) / Volume Resistivity (Ω·cm): The primary measure of conductivity (lower = more conductive). Define your target range (e.g., < 10⁴ Ω/sq for ESD, < 1 Ω/sq for EMI).

EMI Shielding Effectiveness (dB): Required attenuation level across relevant frequencies.

Mechanical Properties: Strength, flexibility (durometer for elastomers), impact resistance, creep resistance – must suit the part’s function.

Environmental Resistance: Temperature range, UV exposure, chemical exposure, humidity, potential for oxidation/corrosion.

Processing Method: Is the compound suitable for injection molding, extrusion, compression molding, overmolding, coating, potting? Filler type impacts flow.

Adhesion: Critical for coatings, sealants, or bonding applications.

Color & Aesthetics: Carbon-filled are typically black. Metal-filled can sometimes be colored, but often have a metallic appearance. Silver offers the best chance for lighter colors.

Cost: Fillers significantly impact cost (Silver > Nickel/Copper > Carbon). Balance performance needs with budget.

Regulatory Compliance: RoHS, REACH, UL recognition, FDA compliance (for food/medical contact) may be required.

Long-Term Stability: Will conductivity degrade over time due to environmental factors or filler settling/migration?

Choosing the Right Compound: A Practical Approach

Define the Primary Function: Is EMI shielding the absolute priority? Or is cost-effective ESD protection sufficient? Is grounding reliability critical?

Set Performance Targets: Quantify required resistivity (surface/volume) or shielding effectiveness (dB). Know your operating environment specs.

Consider Mechanical & Physical Needs: Will it be a rigid part, a flexible gasket, or a coating? What loads or movements will it see?

Evaluate Processing Constraints: How will the part be manufactured?

Identify Regulatory Hurdles: What certifications are mandatory?

Consult with Material Suppliers: Leverage their expertise! Reputable suppliers of conductive plastics, conductive elastomers, and conductive adhesives can:

Recommend specific compounds based on your requirements.

Provide technical data sheets (TDS) with detailed property information.

Offer processing guidance and potentially material samples for testing.

The Future of Conductive Compound

Research focuses on enhancing performance while reducing cost and weight. Key trends include:

Hybrid Fillers: Combining different fillers (e.g., carbon nanotubes with metal flakes) to achieve synergistic benefits.

Improved Dispersion: Ensuring fillers are evenly distributed for consistent performance and better mechanical properties.

Nano-Fillers: Utilizing carbon nanotubes (CNTs) and graphene for high conductivity at lower loadings, improving mechanical properties and opening doors to lighter parts.

Sustainable Solutions: Developing bio-based polymers and recyclable compounds.

Conclusion

Conductive compound are vital enablers in modern technology, solving critical challenges in electronics, energy, and beyond. Understanding the different types (carbon vs. metal-filled), key properties (resistivity, shielding, mechanical), and the selection criteria outlined in this guide is essential. By carefully defining your application needs and collaborating with knowledgeable material suppliers, you can confidently select the optimal conductive compound to ensure the performance, reliability, and safety of your product. Don’t let static, interference, or grounding issues compromise your design – leverage the power of engineered conductive materials.

https://www.inchr-esd.com/product-category/conductive-compound/