Carbon Fiber Reinforced Polymer (CFRP) stands at the forefront of advanced materials, revolutionizing industries from aerospace and automotive to sporting goods and infrastructure. If you’re looking to understand the intricate process behind crafting this advanced material, this guide breaks down the manufacturing steps, key techniques, and emerging trends in CFRP production.

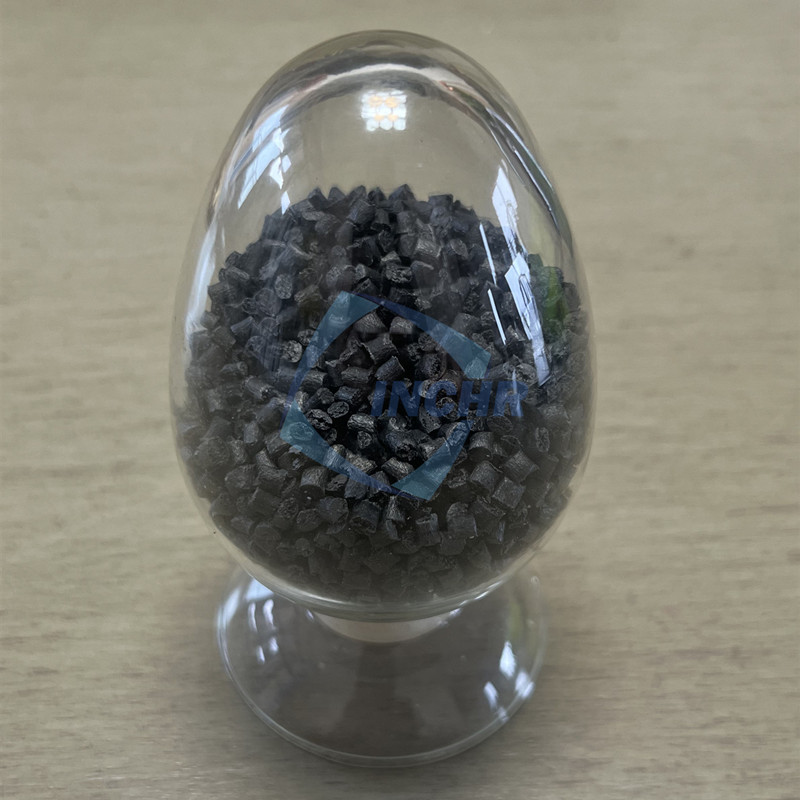

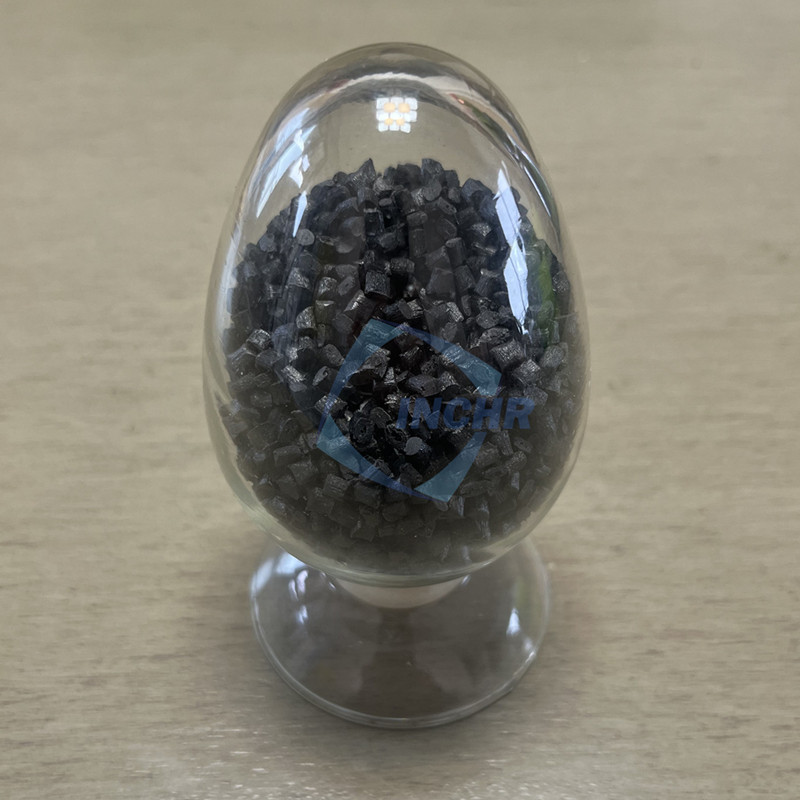

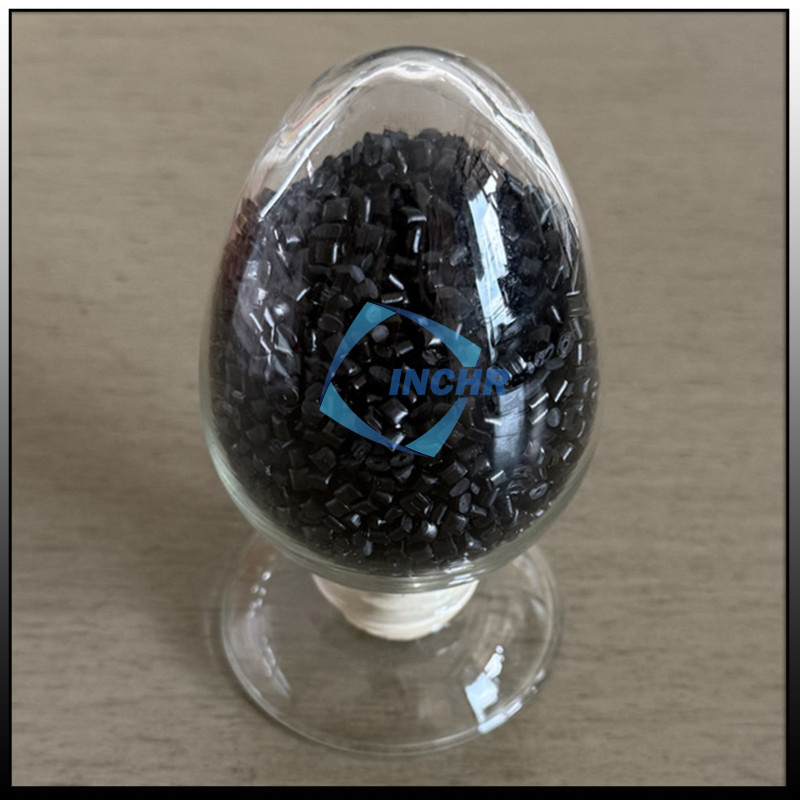

Step 1:Carbon Fiber Reinforced Polymer Material Preparation

The journey begins with selecting high-quality carbon fibers (typically polyacrylonitrile-based) and resin matrices (commonly epoxy or thermoset polymers). Carbon fibers are produced through oxidation and carbonization at temperatures exceeding 1,000°C, resulting in filaments that are woven into fabrics or strands. For sustainable applications, bio-based thermoset polyesters are gaining traction, offering comparable strength with reduced environmental impact.

Step 2:Carbon Fiber Reinforced Polymer Layup: Shaping the Composite

This is where the fiber and resin are combined and shaped into the desired form. Common methods include:

Wet Layup/Hand Layup: Dry fabric is placed into a mold, and liquid resin is manually applied (brushed, rolled, or sprayed).

Prepreg Layup: Fabric pre-impregnated with partially cured (B-staged) resin is cut and placed onto the mold. Precise fiber orientation and resin content are controlled by the prepreg manufacturer. Requires refrigerated storage and handling.

Automated Fiber Placement (AFP) / Automated Tape Laying (ATL): Robotic systems precisely place narrow prepreg tapes or tows onto complex mold surfaces, enabling high accuracy and repeatability for large aerospace structures.

Step 3:Carbon Fiber Reinforced Polymer Molding Techniques

CFRP components are formed using various molding methods:

- Autoclave Curing: Prepreg layups are cured under high pressure (6-7 bar) and temperatures (120-180°C) to eliminate voids and ensure uniform resin distribution.

- Resin Transfer Molding (RTM): Dry fibers are placed in a closed mold, and resin is injected under pressure, ideal for medium-to-high volume production.

- Vacuum Infusion: Resin is drawn through dry fibers using vacuum pressure, offering cost-effective solutions for large structures like wind turbine blades.

- Innovative Methods: Microwave curing, a cutting-edge technique, uses electromagnetic energy to heat CFRP laminates 36 times faster than autoclaves while reducing energy consumption by 99.2%.

Step 4:Carbon Fiber Reinforced Polymer Curing and Post-Processing

After molding, components undergo curing to solidify the resin. Autoclave-cured parts may require post-curing for enhanced heat resistance. Once cured, parts are trimmed, drilled, and finished to meet dimensional specifications. Quality control checks, including ultrasonic testing, ensure no delamination or defects exist.

Step 5: Advanced Trends in Carbon Fiber Reinforced Polymer Manufacturing

- Automation: High-speed systems like Toray’s rapid integrated molding technology produce car roofs in 5 minutes—10 times faster than traditional methods—by bonding foam cores and prepreg skins simultaneously.

- Sustainability: Bio-based resins and recycled carbon fibers are reshaping the industry, with applications in infrastructure and automotive sectors.

- Multi-Material Integration: Hybrid designs combining CFRP with metals or foams optimize performance for aerospace and electric vehicles (EVs).

Conclusion

Manufacturing Carbon Fiber Reinforced Polymer demands precision, innovation, and adaptability to evolving technologies. From material selection to automated curing, each step plays a critical role in delivering components that excel in strength, weight, and sustainability. By staying informed about trends like automation and eco-friendly materials, manufacturers can unlock new possibilities in industries ranging from renewable energy to transportation.

Ready to optimize your CFRP production? Explore our ultimate guide to CFRP quality control for actionable insights.