Carbon Fiber Reinforced Polymer (CFRP), often simply called carbon fiber composite, is no longer just the stuff of exotic supercars and spacecraft. This advanced material is revolutionizing product design and manufacturing across countless sectors. But what exactly makes CFRP so special, and where is it making the biggest impact?

What is Carbon Fiber Reinforced Polymer?

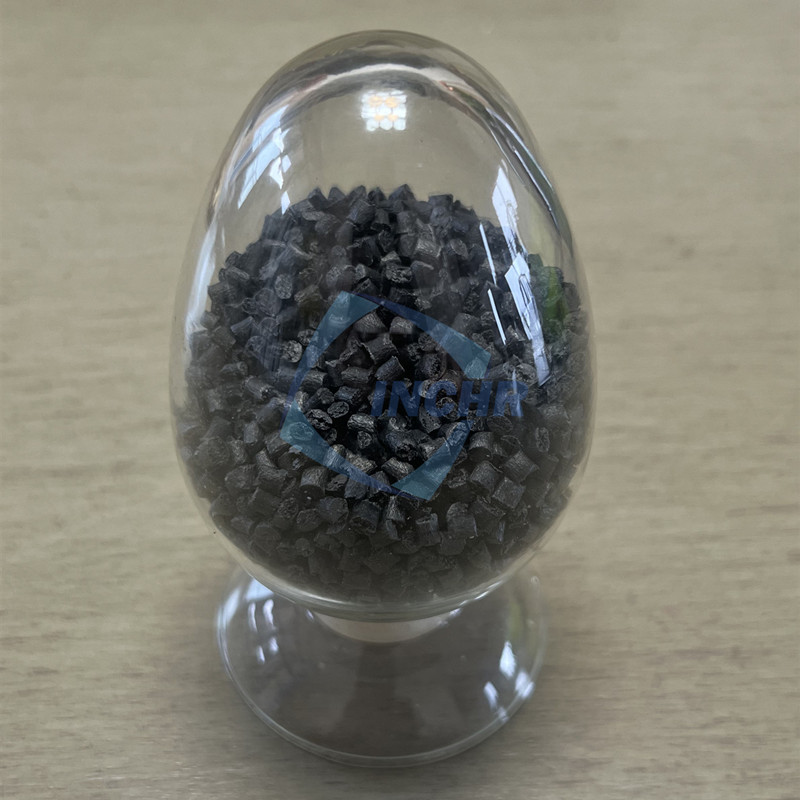

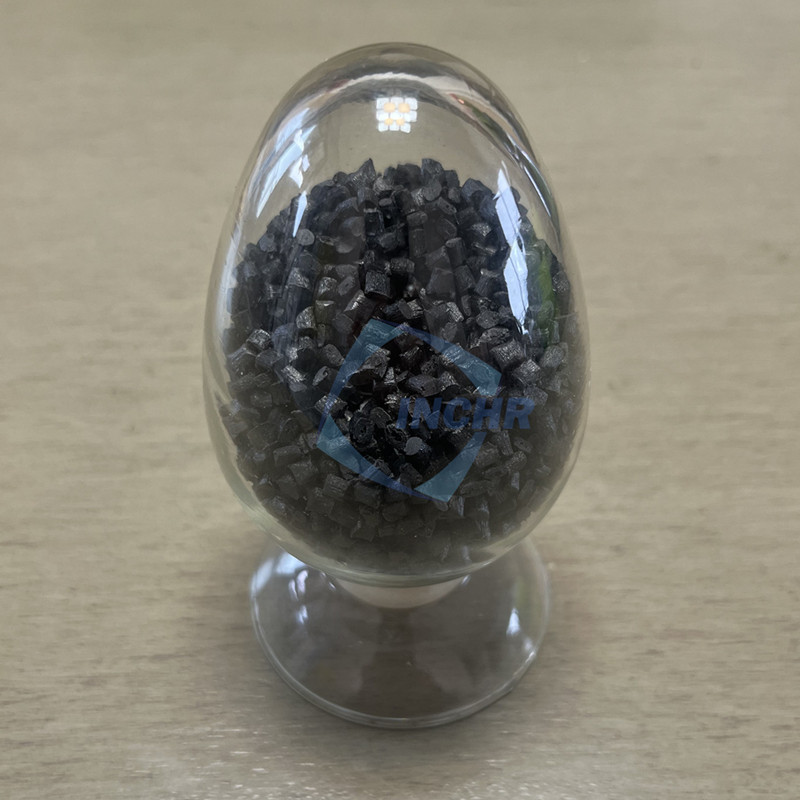

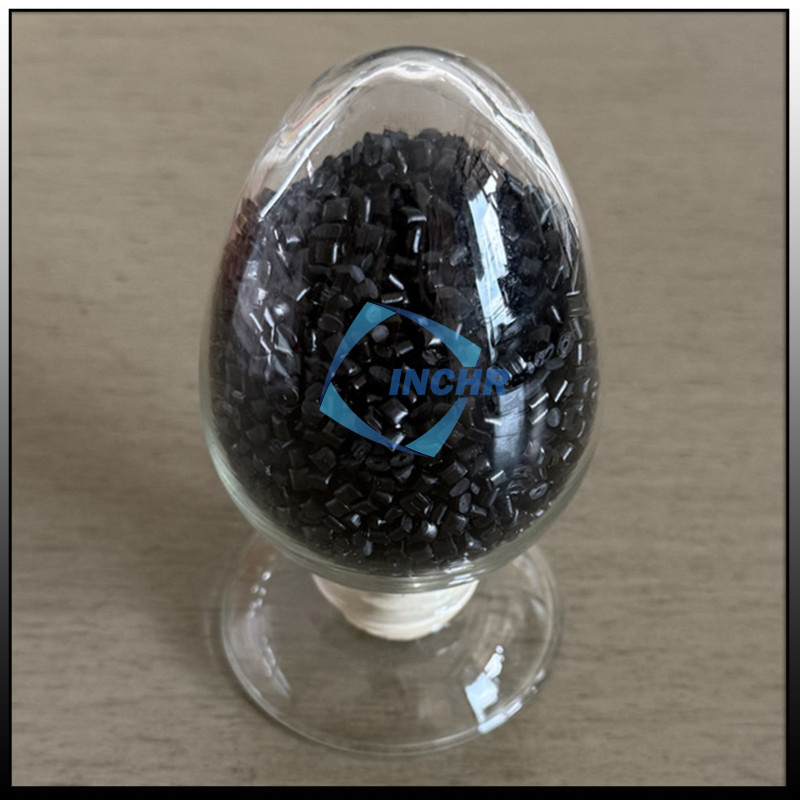

At its core, CFRP combines two distinct materials:

Reinforcement: Extremely thin, incredibly strong carbon fibers (typically 5-10 micrometers in diameter).

Matrix: A polymer resin (often epoxy, polyester, or vinyl ester) that binds the fibers together, transfers loads between them, and protects them.

The magic lies in the synergy. The carbon fibers provide exceptional tensile strength and stiffness, while the polymer matrix distributes stress, maintains fiber alignment, and gives the composite its shape. The fibers are usually woven into fabrics or arranged in specific orientations within the matrix to optimize properties for the intended load direction.

Key Properties of Carbon Fiber Reinforced Polymer

The unique combination in CFRP delivers a set of properties unmatched by traditional materials like steel or aluminum:

Exceptional Strength-to-Weight Ratio: This is CFRP’s superstar feature. It can be 5 times stronger than steel yet only a fraction of the weight. This translates directly into lighter, more fuel-efficient vehicles, longer-range aircraft, and easier-to-handle equipment.

High Stiffness (Modulus of Elasticity): CFRP is incredibly rigid, resisting deformation under load far better than metals of comparable weight. This is crucial for precision components and structures needing minimal flex.

Outstanding Fatigue Resistance: CFRP composites excel at withstanding repeated loading and unloading cycles without failing, a critical advantage in aerospace and automotive applications.

Corrosion Resistance: Unlike metals, CFRP is highly resistant to corrosion from chemicals, salt water, and weathering, significantly reducing maintenance needs and lifespan costs.

Low Thermal Expansion: CFRP expands and contracts very little with temperature changes, making it ideal for applications requiring dimensional stability (e.g., optical benches, satellite components).

Design Flexibility: The ability to tailor the fiber orientation and layering allows engineers to precisely engineer the strength and stiffness exactly where needed in a part, optimizing performance and minimizing material waste.

X-Ray Translucency: Most CFRPs are radiolucent, making them valuable in medical imaging applications.

Industrial Applications of Carbon Fiber Reinforced Polymer

The properties of CFRP drive its adoption in demanding sectors:

Aerospace & Aviation: The ultimate proving ground. CFRP is fundamental in modern aircraft (like the Boeing 787 Dreamliner and Airbus A350), used extensively in wings, fuselages, tail sections, and interior components. Weight savings here directly equal massive fuel savings and reduced emissions. [ Future of Composites in Aerospace]

Automotive & Motorsport: From Formula 1 monocoques to high-performance road car chassis, body panels, and wheels, CFRP reduces weight, boosts acceleration and handling, and improves energy efficiency. Its use is expanding into mainstream electric vehicles to offset heavy battery weight and extend range.

Wind Energy: Giant wind turbine blades are almost exclusively made from CFRP composites. The material’s stiffness, strength, light weight, and fatigue resistance are essential for capturing maximum energy efficiently and withstanding harsh environmental loads for decades.

Sporting Goods: Tennis rackets, golf club shafts, bicycle frames (road, MTB, track), fishing rods, hockey sticks – CFRP provides the perfect blend of lightness, stiffness, and strength for peak athletic performance and durability.

Medical Devices: CFRP’s strength, lightness, and radiolucency make it ideal for X-ray tables, prosthetics, orthotic braces, and surgical instrument components.

Civil Engineering & Infrastructure: CFRP sheets and strips are used to retrofit and strengthen aging concrete structures (bridges, buildings, parking garages). CFRP rebar offers a corrosion-resistant alternative to steel in concrete.

Industrial Equipment: Robotics arms benefit from CFRP’s stiffness and light weight, enabling faster, more precise movements with less energy. Drive shafts, rollers, and machine covers also leverage its properties.

Consumer Electronics: High-end laptops, drones, camera tripods, and even smartphone cases utilize CFRP for its premium look, feel, and structural advantages.

The Future of Carbon Fiber Reinforced Polymer

While CFRP offers immense benefits, challenges remain, primarily cost (driven by raw materials and complex manufacturing) and recyclability. However, intense research is focused on:

Reducing Costs: Developing cheaper precursor materials and faster, more automated production processes (like automated tape laying – ATL).

Improving Recyclability: Advancing techniques for reclaiming carbon fibers from end-of-life components.

Enhancing Performance: Developing new resin systems (like thermoplastic Carbon Fiber Reinforced Polymer ) for better impact resistance, faster processing, and easier repairability.

Conclusion

Carbon Fiber Reinforced Polymer is a transformative material, enabling lighter, stronger, and more efficient products across a vast spectrum of industries. Its unparalleled strength-to-weight ratio, stiffness, and corrosion resistance make it indispensable where performance and weight savings are paramount. As manufacturing costs decrease and recycling solutions mature, we can expect CFRP to penetrate even more mainstream applications, continuing to reshape the engineered world around us. From soaring through the skies to powering our vehicles and enhancing our daily lives, CFRP is truly the lightweight titan of modern materials.