The car industry craves efficiency, performance, and safety. Carbon Fiber Reinforced Polymer (CFRP) delivers all three. This advanced material is changing how cars are built. Let’s explore its key roles.

1. Carbon Fiber Reinforced Polymer Big Win: Massive Weight Loss

CFRP is incredibly strong yet super light. It’s often:

50-70% lighter than steel

30-50% lighter than aluminum

Better Fuel Economy (ICE): Less weight = less fuel burned.

Longer EV Range: Less mass = smaller battery needed for the same distance. Crucial for EV adoption!

Sharper Handling & Braking: Lighter cars accelerate faster, stop quicker, and corner better.

Smarter Design: Saved weight allows for bigger batteries or extra features without adding bulk.

2. Safety First? Absolutely!

Light doesn’t mean weak. CFRP excels at absorbing crash energy. It crushes in a controlled way. This makes it perfect for:

Protective Cages: CFRP safety cells (like in race cars) shield passengers.

Crash Zones: Bumpers and structures made to absorb impact safely.

Dent Resistance: Better than metal against minor bumps and scrapes.

3.Carbon Fiber Reinforced Polymer Design Freedom Unleashed

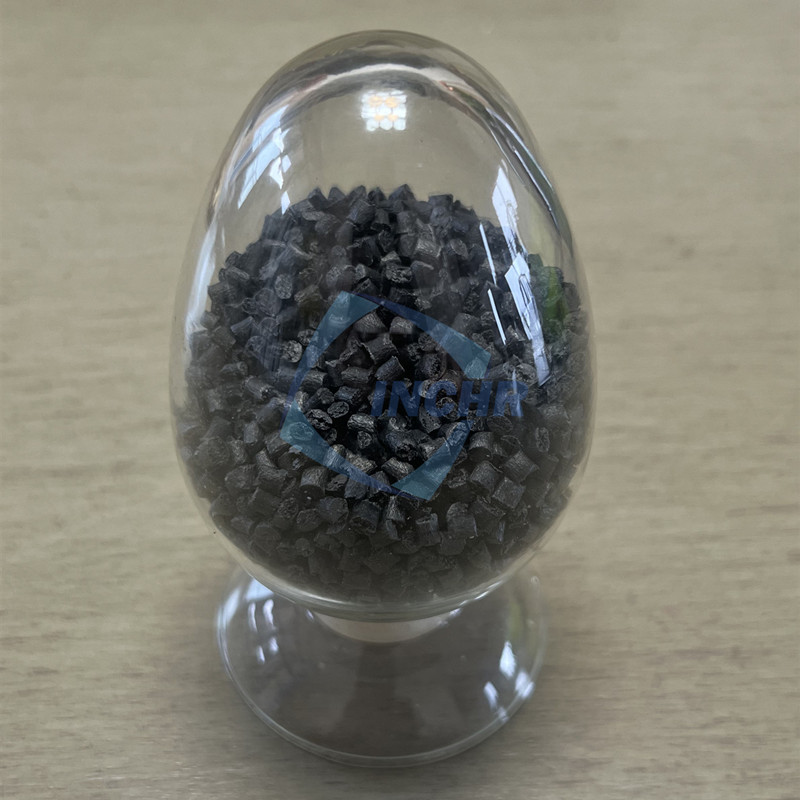

CFRP can be molded into complex shapes (using processes like Resin Transfer Molding – RTM). This allows:

Fewer Parts: Combine multiple pieces into one CFRP component. Saves weight and assembly time.

Sleeker Aerodynamics: Smoother shapes cut through air easier, boosting efficiency.

More Space: Thinner, stronger sections free up room for batteries or passengers.

4. Tough & Long-Lasting

CFRP fights corrosion. Unlike steel or aluminum, it won’t rust from salt or moisture. This means:

Longer Lifespan: Parts last longer.

Lower Maintenance: Fewer corrosion-related repairs.

5. Powering the Electric & Sustainable Future

CFRP is vital for electric cars:

Maximizing EV Range: Its weight savings directly counter heavy batteries – the top EV challenge.

Next-Gen Batteries: Research uses CFRP as part of the battery structure itself for ultimate efficiency.

Eco-Potential: Long life and no corrosion aid sustainability. Recycling tech is advancing fast!

Challenges & What’s Next

Cost and production speed still limit CFRP in everyday cars. But progress is rapid:

Automated manufacturing is speeding things up.

Cheaper materials are being developed.

Better recycling is coming.

The focus is smart use: applying CFRP where it offers the biggest payoff – key structures, battery packs, and high-stress parts.

Conclusion: Carbon Fiber Reinforced Polymer is a Game-Changer

Carbon Fiber Reinforced Polymer is transforming autos. It’s not just lighter; it enables:

More practical EVs

Safer vehicles

Better performance

Innovative designs

As costs fall, expect CFRP to move from supercars into mainstream vehicles. The future of driving is being built with carbon fiber.