Carbon Fiber Reinforced Polymer Composites (CFRP) are synonymous with high performance. Their legendary strength-to-weight ratio, stiffness, and corrosion resistance make them aerospace darlings and automotive innovators. But when these “wonder materials” enter ESD-sensitive environments like electronics manufacturing, semiconductor cleanrooms, or medical device assembly, standard off-the-shelf CFRP often become a liability, not an asset. At INCHR-ESD, we engineer CFRP solutions that deliver structural excellence without compromising electrostatic discharge (ESD) safety.

The Hidden Risk of Conventional Carbon Fiber Reinforced Polymer in ESD Zones

While carbon fiber itself is conductive, the polymer matrix (typically epoxy, vinyl ester, or thermoplastic) surrounding it is usually an excellent insulator. This creates a critical problem:

Surface Resistivity Variability: The conductive carbon fibers are embedded deep within the insulating resin. Surface contact often only touches the resin, resulting in high surface resistivity (>10^12 Ω/sq) – firmly in the insulative range per ANSI/ESD S20.20. This allows dangerous static charges to build up.

Ineffective Charge Dissipation: Even if fibers are exposed at the surface (through machining or wear), the path for charge to flow through the composite to ground is often discontinuous and unreliable. Charge dissipation is slow and unpredictable.

Tribocharging Hotspots: Friction between CFRP components or against other materials (e.g., PCBs, plastic trays) readily generates significant static charges due to the insulating resin surface.

Contamination Magnet: Static charges attract airborne particulates and dust, a critical concern in cleanrooms and precision assembly.

Consequences in ESD-Protected Areas (EPAs):

Component Damage: Uncontrolled discharge from a charged CFRP jig, fixture, or tooling can zap sensitive microelectronics (ICs, MOSFETs, PCBs), causing latent or catastrophic failures.

Process Disruptions: Static attraction can misalign small components or cause automated handling systems to malfunction.

Safety Hazards: In environments with flammable solvents or gases, an electrostatic spark from CFRP poses an ignition risk.

Failed Audits: Facilities failing to meet ANSI/ESD S20.20 or IEC 61340-5-1 surface resistance/static decay requirements risk losing certifications.

Beyond Coating: The Quest for True ESD-Safe Carbon Fiber Reinforced Polypmer Composites

Many attempt quick fixes like topical antistatic sprays or conductive paints. These fail for critical applications:

Wear & Abrasion: Coatings quickly wear off high-contact areas like fixture locators or conveyor guides.

Chemical Sensitivity: Cleanroom solvents degrade many coatings.

Inconsistency: Application thickness varies, leading to unpredictable surface resistance.

Delamination: Coatings can peel, creating insulating islands and conductive hazards simultaneously.

Not Permanent: Requires constant reapplication and monitoring.

Engineered ESD-Safe Carbon Fiber Reinforced Polymer Composites: How INCHR-ESD Delivers Reliable Performance

True ESD safety in CFRP requires integrating conductivity throughout the material system and ensuring reliable surface charge dissipation. Our approach focuses on intrinsic, permanent ESD properties:

Conductive Matrix Selection & Modification:

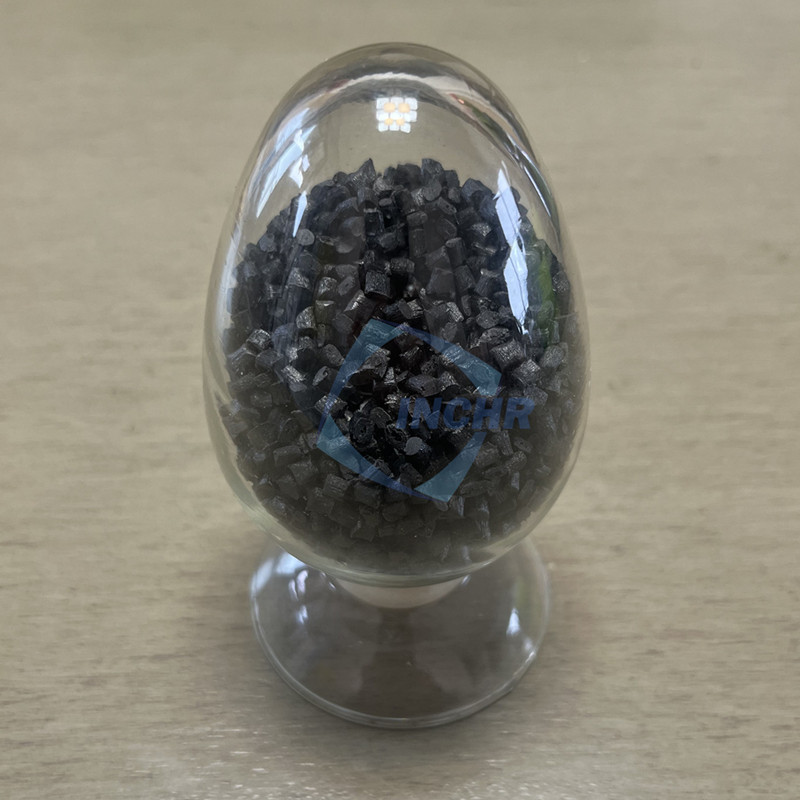

We utilize specialized inherently static-dissipative or conductive polymer resins as the matrix (e.g., modified PEEK, PEI, Nylon, Epoxy systems). These resins possess bulk conductivity.

Proprietary Additive Systems: We compound synergistic conductive additives (e.g., specific carbon blacks, carbon nanotubes, metallic particles) into the resin itself before combining with carbon fiber. This creates a percolation network within the matrix.

Optimized Fiber-Matrix Interface:

Surface treatments on the carbon fiber ensure strong bonding and, crucially, effective electrical contact between the conductive fibers and the now-conductive matrix. This bridges the insulating gap.

Controlled Surface Resistivity:

The combination of conductive matrix, optimized interface, and exposed conductive fibers results in consistent, homogeneous surface resistivity across the part, typically within the optimal static dissipative range (10^4 to 10^9 Ω/sq). This enables safe, controlled charge bleed-off to ground.

Material Synergy:

The carbon fiber reinforcement continues to provide exceptional strength, stiffness, and dimensional stability. The engineered conductive matrix adds the essential ESD functionality without sacrificing core mechanical properties. We achieve the coveted trifecta: Lightweight + Strong + ESD-Safe.

Carbon Fiber Reinforced Polymer Composites: Engineered for Demanding ESD Applications

Our specialized Carbon Fiber Reinforced Polymer Composites solve critical challenges where standard CFRPs fail:

Precision Fixturing & Jigs: Machined CFRP fixtures for PCB assembly, semiconductor test sockets, or automated handling – ensuring components never face ESD risk from the tool itself. (Benefit: Protects sensitive components, ensures placement accuracy)

Robotic End-Effectors & Arms: Lightweight CFRP arms for cleanroom robots handling wafers or devices. (Benefit: Reduced inertia for faster movement, ESD safety, no particle shedding)

Durable Work Surfaces & Shelving: Ultra-strong, lightweight ESD-safe workstations and storage for EPA zones. (Benefit: Superior load-bearing, chemical resistance, permanent ESD)

Medical Device Components: Surgical tooling, imaging equipment parts requiring high strength, radiolucency (X-ray transparency), and ESD safety. (Benefit: Biocompatibility options, sterilizability, EMI/RFI shielding possible)

Aerospace & Defense Interiors: Non-metallic brackets, panels, and housings needing ESD properties for avionics protection. (Benefit: Weight savings, corrosion resistance, meets flammability standards like FAR 25.853)

Choosing the Right ESD-Safe Carbon Fiber Reinforced Polymer Composites: Key Considerations

Required Surface Resistivity: Confirm the target range (e.g., 10^5-10^8 Ω/sq common for EPAs).

Mechanical Loads: Define tensile/compressive strength, stiffness (modulus), and impact requirements.

Environmental Exposure: Temperature range (cryo to >150°C?), chemicals, UV, humidity.

Cleanliness Class: Particle generation and outgassing levels (e.g., for ISO Class cleanrooms).

Regulatory Compliance: ESD standards (S20.20, 61340), flammability (UL94, FAR), FDA, USP Class VI, REACH/RoHS.

Fabrication Complexity: Can the design be efficiently machined from plate/block, or does it require molding?

The INCHR-ESD Advantage: More Than Just Material

Deep Material Science Expertise: We don’t just supply CFRP; we engineer the right composite system for your specific ESD and structural needs.

Proven Formulations: Rigorously tested resins and additives ensure reliable, permanent ESD performance.

Precision Machining & Fabrication: State-of-the-art CNC machining centers handle complex CFRP geometries with tight tolerances.

Full Traceability & Certification: Material certifications and test reports (surface resistance, static decay, mechanical properties) provided.

Collaborative Problem Solving: From design review to material selection and final part validation, we partner with you.

Stop Compromising. Engineer Safety In.

Don’t let the limitations of standard Carbon Fiber Reinforced Polymer Composites jeopardize your sensitive electronics or processes. Move beyond unreliable coatings and embrace CFRP engineered from the molecule up for guaranteed ESD protection.

Unlock the True Potential of ESD-Safe Carbon Fiber Reinforced Polymer Composites:

Explore Our ESD-CFRP Material Solutions: https://www.inchr-esd.com/product-category/carbon-fiber-reinforced-plastic/

inchr-esd.com: Where Advanced Composites Meet Uncompromising ESD Safety.