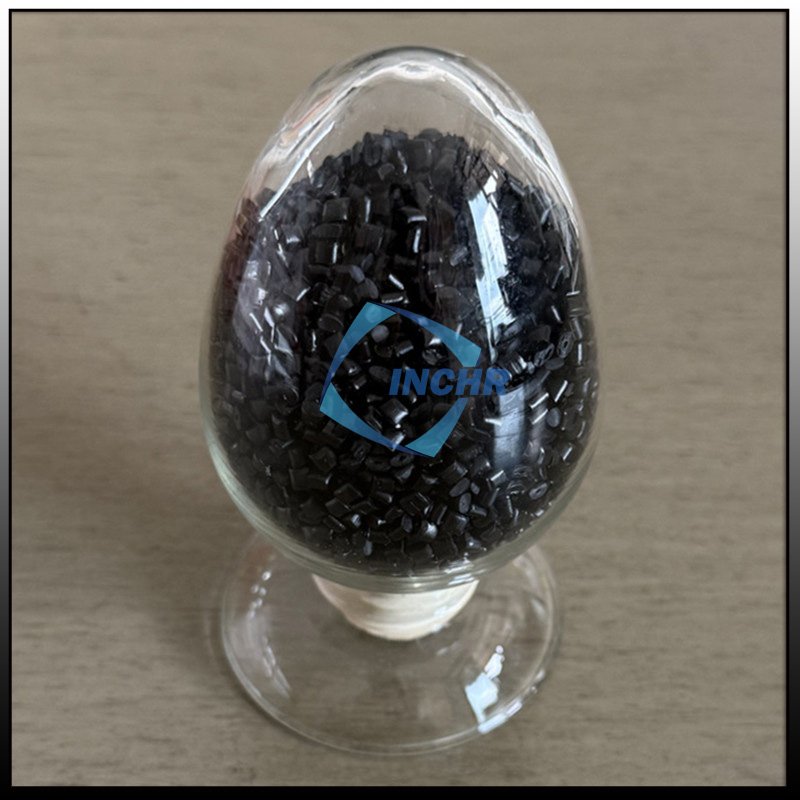

Carbon Fiber Reinforced Plastic (CFRP) has emerged as a cornerstone of modern advanced materials, revolutionizing industries that demand high strength, low weight, and exceptional durability. This composite material, consisting of carbon fibers embedded in a polymer resin matrix, continues to see significant technical progress, expanding its applications and performance boundaries.

Recent Technical Advancements

The evolution of CFRP is marked by innovations in manufacturing and material science. Automated fiber placement (AFP) and automated tape laying (ATL) technologies have drastically improved production rates and precision, reducing costs and waste. These advancements allow for the creation of larger, more complex components with consistent quality, which is critical for sectors like aerospace.

Furthermore, the development of new resin systems, including thermoplastic and bio-based resins, enhances sustainability and recyclability. Thermoplastic CFRP’s can be reheated and reformed, simplifying repair and end-of-life recycling—a significant step toward addressing environmental concerns. Research into nano-engineered composites, incorporating materials like carbon nanotubes or graphene, is pushing the mechanical properties of CFRP even further, offering improved toughness and electrical conductivity.

Expanding Applications Of Carbon Fiber Reinforce Plastic

In aerospace, its use has expanded from secondary structures to primary components like fuselages and wings, notably in aircraft such as the Boeing 787 and Airbus A350. The automotive industry leverages CFRP for high-performance vehicles (e.g., BMW i3) to reduce weight and improve energy efficiency.

In renewable energy, CFRP is the material of choice for massive wind turbine blades, enabling longer, more efficient designs that capture more wind energy.

Challenges and Future Outlook Of Carbon Fiber Reinforce Plastic

Despite its advantages, CFRP faces challenges, particularly in cost and recyclability. However, ongoing research into efficient recycling methods, such as pyrolysis and solvolysis, promises a more sustainable lifecycle. The integration of digital twins and AI in design and manufacturing is also optimizing CFRP use, predicting performance and failure modes more accurately.

As technology progresses, Carbon Fiber Reinforced Plastic is set to become even more integral to sustainable engineering solutions, from next-generation transportation to infrastructure.Learn more about the properties of CFRP on our site.