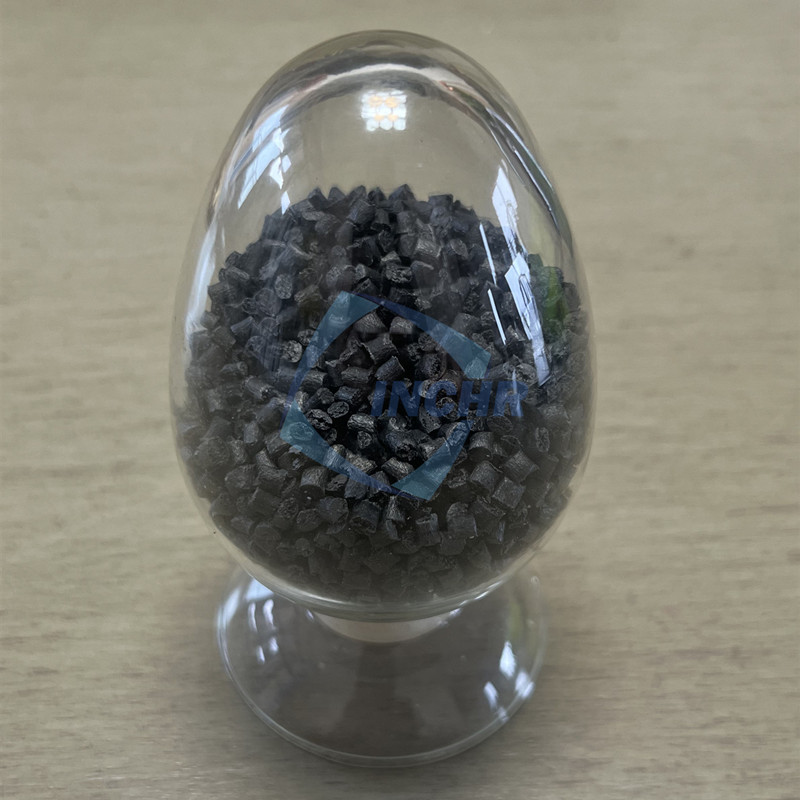

In today’s pursuit of lightweight and high-strength materials, carbon fiber reinforced nylon (PA-CF) has emerged as an innovative composite solution revolutionizing multiple industries. This advanced material combines the excellent mechanical properties of carbon fiber with the processing advantages of nylon, creating unprecedented value for engineering applications.

1. Core Advantages

- 55% Weight Reduction: With 15-30% carbon fiber content, density decreases to 1.3-1.4g/cm³

- 200% Strength Increase: Tensile strength reaches 150-200MPa

- Thermal Stability: Continuous service temperature up to 120-150℃

- Precision Molding: 0.1-0.3% shrinkage rate ensures dimensional accuracy

2. Industry Applications

Automotive Manufacturing

PA-CF components reduce vehicle weight by 15-20%, improving energy efficiency while maintaining structural integrity. Typical uses include:

- Electronic throttle bodies

- Transmission system gears

- Battery module brackets

Consumer Electronics

Ultra-thin laptop frames (0.8mm thickness) and smartphone middle frames demonstrate perfect balance between strength and lightweight design.

3. Technical Breakthroughs

- Recent innovations include:

- 3D printing filaments with 40% carbon fiber content

- Electrically conductive grades (10³-10⁶ Ω·cm)

4. Sustainability

PA-CF composites support circular economy:

- 85% material recovery rate

- 30% lower carbon footprint vs aluminum alloys

- Compatible with green production processes

Conclusion

As a cutting-edge engineering plastic, Carbon fiber reinforced nylon continues to expand its application boundaries. From automotive lightweighting to aerospace innovations, this material is writing a new chapter in industrial manufacturing. Enterprises seeking technological upgrades should consider PA-CF composites as a strategic material choice.

Contact our material engineers today to obtain free samples and technical solutions tailored to your application requirements.