Carbon fiber reinforced composites (CFRPs) are revolutionizing industries from aerospace to sports. But what makes this “black gold” so exceptional? Let’s explore their mechanics and defining properties.

The Science Behind Carbon Fiber Reinforced Composites

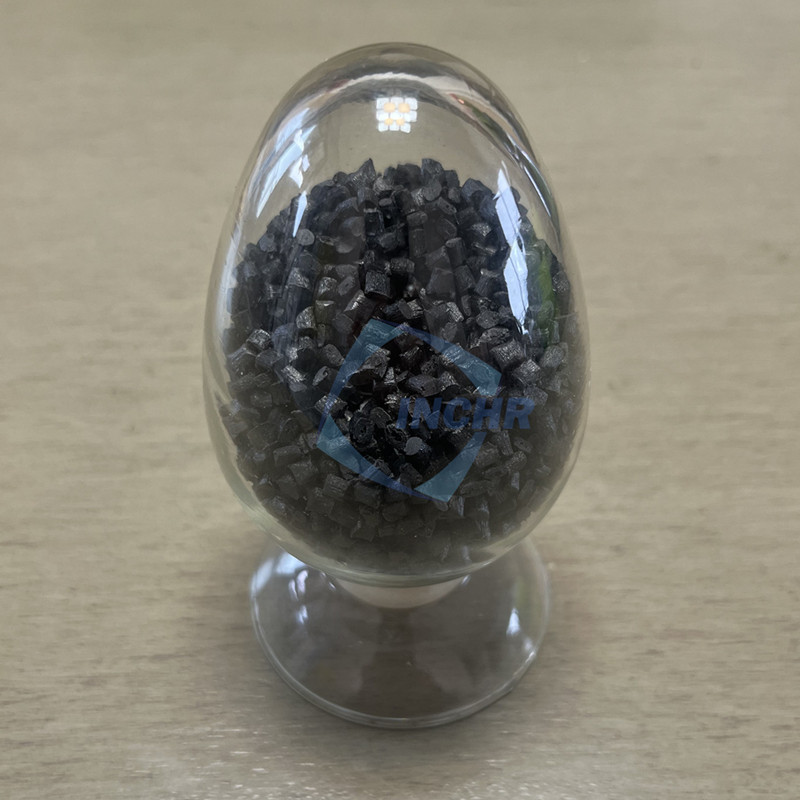

CFRPs aren’t a single material—they’re a synergistic duo acting like a high-performance team:

1. Carbon Fibers: The Strength Core

Role: Provide unparalleled tensile strength and stiffness.

Production: Precursor materials (e.g., polyacrylonitrile) are heated in inert atmospheres, stripping non-carbon atoms to create pure crystalline carbon strands (5-10μm thick).

Advantage: Surpasses steel in strength-to-weight ratio while resisting deformation.

2. The Matrix: The Unifying Force

Typically polymer resins (epoxy/polyester), the matrix performs critical functions:

Binding fibers into cohesive structures

Distributing stress evenly across fibers

Shielding fibers from impact, moisture, and chemicals

Enabling complex molding for custom geometries

Manufacturing: Where Magic Happens

Fibers are woven into fabrics, infused with resin, and cured under heat/pressure. Engineers strategically orient fibers during layup to align strength with load paths—a key advantage over isotropic metals. https://www.inchr-esd.com/carbon-fiber-reinforced-composites-strength-meets-versatility/→

Key Properties Driving Adoption

✅ Ultra-High Strength-to-Weight Ratio

CFRPs outperform metals like aluminum, enabling lighter aircraft (boosting fuel efficiency) and high-performance gear.

✅ Superior Stiffness-to-Weight Ratio

Resists deformation under load, critical for precision applications: robotics, telescope mounts, and bike frames.

✅ Exceptional Fatigue Resistance

Withstands repetitive stress better than metals, extending lifespans of wind turbine blades and aircraft wings.

✅ Corrosion Immunity

No rust or chemical degradation, ideal for marine/chemical environments.

✅ Minimal Thermal Expansion

Stable dimensions across temperature swings suit precision instruments.

✅ Tailored Anisotropy

Fiber orientation customizes strength directionality, enabling impossible metal designs.

✅ Vibration Damping

Absorbs energy for quieter machinery and automotive parts.

Key considerations for carbon fiber reinforced composites

⚠️ Electrical Conductivity

Advantageous for lightning protection (aircraft), but risks galvanic corrosion near metals.

⚠️ Recycling Complexity

Thermoset CFRPs are hard to recycle—driving R&D for sustainable solutions.

⚠️ Directional Sensitivity

Strength plummets perpendicular to fibers; designs must account for anisotropy.

Conclusion

CFRPs merge lightweight design with extreme strength, driving innovation from F1 cars to medical implants. While cost and recycling remain challenges, their unmatched properties cement them as the future of high-performance materials. Master their principles to unlock next-gen engineering potential.