Anti static for plastic refers to taking a series of measures or using specific methods to enable plastic products to have the ability to reduce or eliminate the generation and accumulation of static electricity. Solution of anti static for plastic usually involves adding antistatic agents during the production process of plastics, changing the molecular structure or surface properties of plastics to increase their conductivity, so that the generated static electricity can be quickly dissipated or conducted away, and avoiding static electricity from accumulating on the surface of plastic products to a degree sufficient to produce adverse effects, such as adsorbing dust, causing electric shock, interfering with the operation of electronic equipment, or causing fire and explosion hazards.

Why is anti static for plastic necessary?

Plastic static electricity refers to the charge imbalance phenomenon that occurs on the surface or inside of plastic materials.

Because plastics usually have high resistivity, there are few free electrons inside them, and it is difficult for charges to move freely. When plastics rub, contact, and separate from other objects, electrons will transfer between them, causing one side to lose electrons and become positively charged, and the other side to gain electrons and become negatively charged, thereby generating static electricity on the plastic surface.

First of all, in some specific industrial production and processing processes, the generation of static electricity may cause dangers such as fire or explosion. For example, in an environment with flammable gases, liquids, or dust, static discharge on the surface of plastics may become an ignition source.

Secondly, static electricity will absorb dust and tiny particles, which will seriously affect the quality and performance of products that need to be kept clean and high-precision, such as electronic components, optical instruments, etc. Furthermore, static electricity may cause problems such as adhesion and clogging of plastic materials during processing, transportation, or packaging, affecting production efficiency and product consistency. In addition, for some plastic products that are in direct contact with the human body, such as plastic seats, armrests, etc., the accumulation of static electricity may cause discomfort or even electric shock to the user. Finally, plastic parts used in some electronic devices, if they carry static electricity, may interfere with the normal operation of the equipment, causing signal distortion, circuit failure, and other problems.

Anti static for plastic is the fundamental way to solve the problem of static electricity. It is indispensable in modern industrial production and manufacturing.

How to improve the performance of anti static for plastic?

How to improve the performance of anti static for plastic?

- Add antistatic agent: Add an appropriate amount of antistatic agent during the plastic production process. Antistatic agents can increase the conductivity of plastic so that the charge dissipates faster to achieve the anti static for plastic.

- Increase environmental humidity: Appropriately increase the humidity of the environment in which plastic products are located because high humidity helps the conduction and dissipation of charges.

- Surface treatment: Treat the surface of plastic products, such as plasma treatment, corona treatment, etc., to change the chemical and physical properties of the surface and improve conductivity.

- Grounding: Connect the plastic product to the grounding device so that the generated static electricity can be introduced into the earth in time.

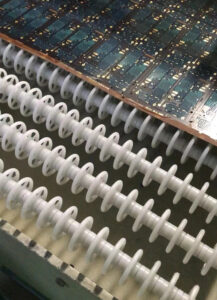

- Choose conductive or antistatic plastic materials: In the product design stage, choose plastic materials with good conductive or antistatic properties to improve the performance anti static for plastic.

- Optimize production process: Adjust production process parameters such as injection molding and extrusion to reduce the generation of static electricity.

- Coating treatment: Apply an antistatic coating on the surface of the plastic product to prevent static electricity accumulation.