Products

Customizable ESD plastic materials for ESD protection

INCHR is a high-tech enterprise specializing in ESD plastic materials. The company was established in 2012 and has multiple independent research and development patents. INCHR has advanced cutting-edge technology, standardized production and R&D equipment, and excellent after-sales service. In response to the needs of global customers for different ESD plastic materials, we have a professional development team with many years of experience and can provide a one-stop solution for ESD protection. We can quickly provide customized formulas and services to win the trust of customers.

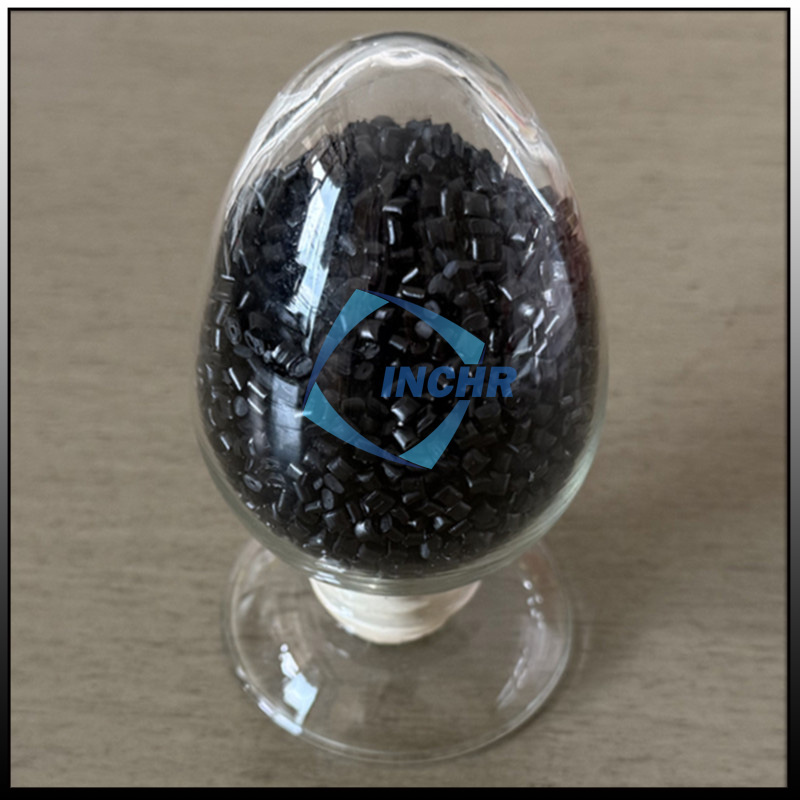

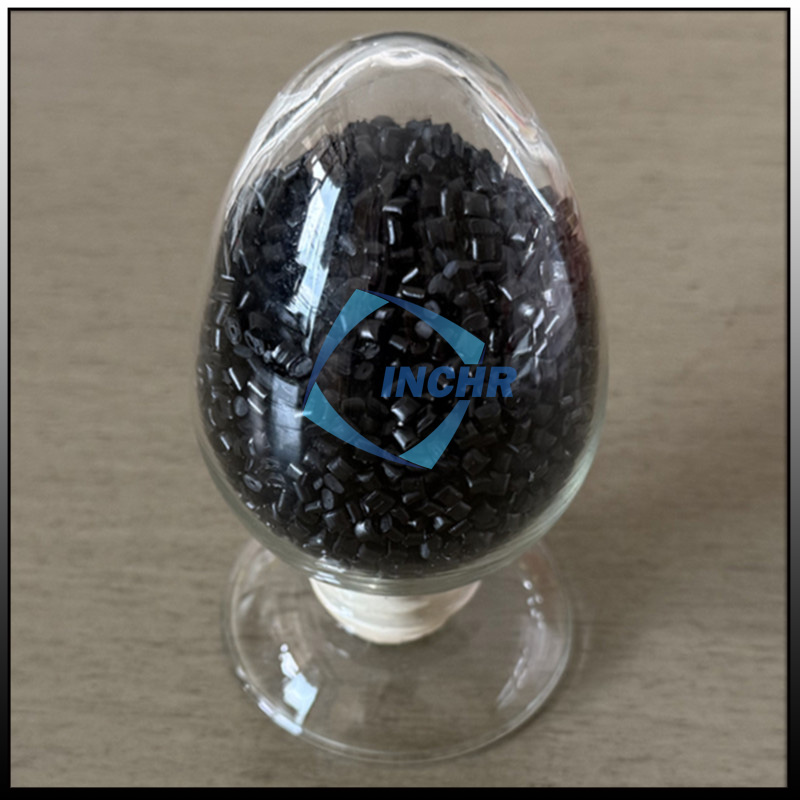

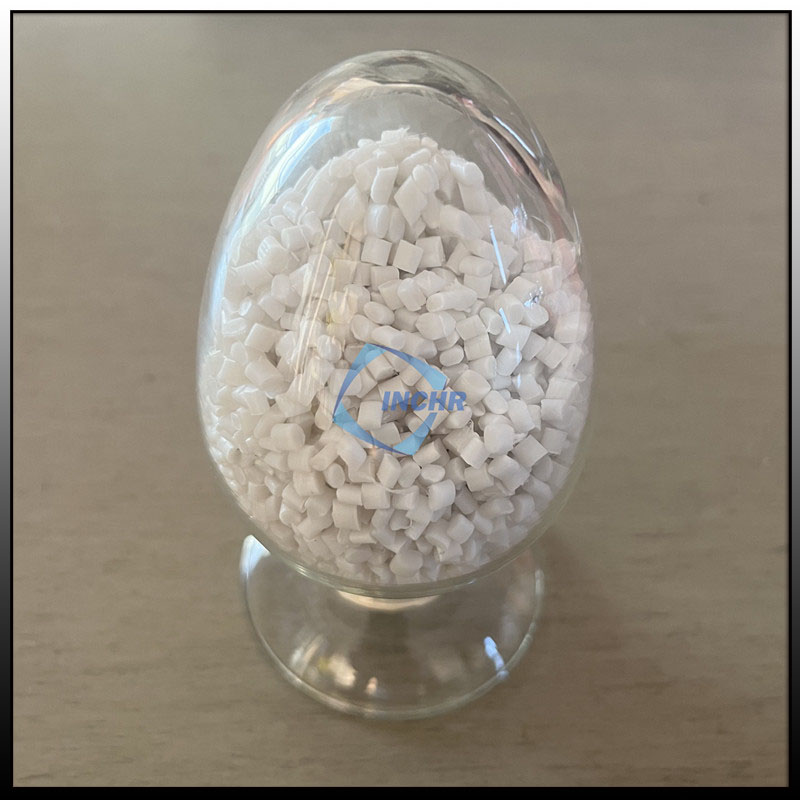

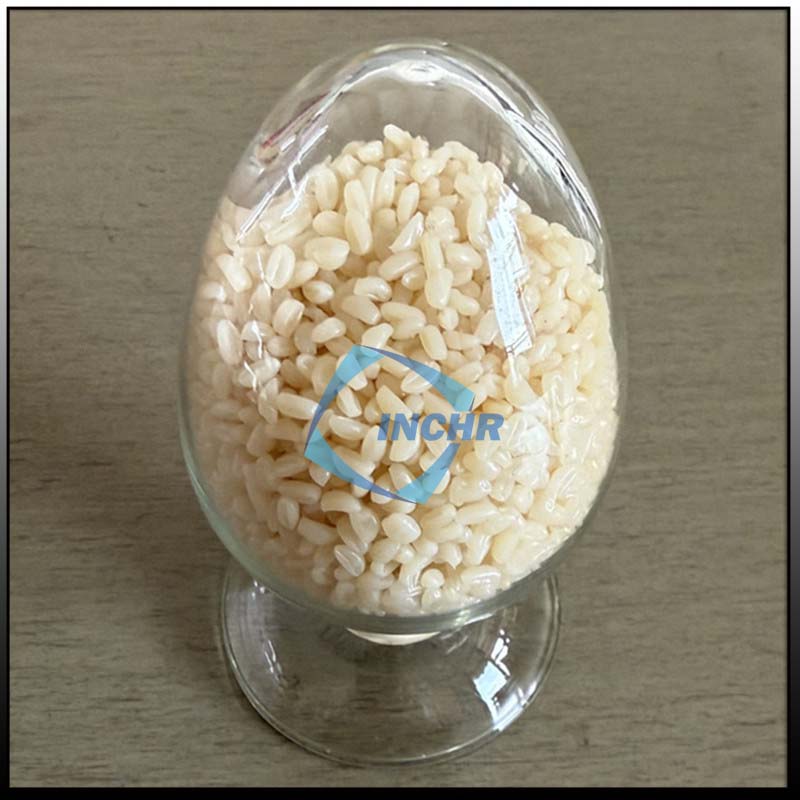

NCHR@ESD plastic materials are divided into antistatic grade(surface resistance 10^9~10^12 Ω ), static elimination grade(surface resistance 10^6~10^9 Ω ), conductive grade(surface resistance 10^3~10^5 Ω ), and EMI shielding grade(surface resistance 10^-2~10^3 Ω ). All ESD plastic materials exist in the form of particles and are suitable for different processing technologies such as injection molding, extrusion, blown film, foaming, cast film, etc. The resistance value, color, mechanical properties, etc. of the material can be customized.

Advantages of INCHR@ESD plastic material

More cost-effective than competitors: Permanent antistatic agents and permanent antistatic masterbatch are our best-selling products. Our market price is three-quarters of our competitors, which can save customers 25% of costs. The permanent antistatic agent is an important component of ESD plastic materials. It is a chemical substance that can effectively give materials antistatic properties for a long time. It is different from traditional antistatic agents. The effect of traditional antistatic agents may weaken over time or changes in usage conditions, while permanent antistatic agents can maintain a stable antistatic effect throughout the service life of the material. The permanent antistatic masterbatch is a granular substance made by mixing an antistatic agent with carrier resin in a certain proportion through a specific process. Its main function is to facilitate the uniform addition of antistatic agents during the processing of materials so that the final product has good and stable antistatic properties.

Multiple selections of matrix substances: Carbon black, carbon nanotubes, stainless steel metal fibers, graphene, and carbon fibers can all be matrix material options for our conductive composites. We select appropriate matrix materials to synthesize conductive composites based on different resistance values, mechanical performance requirements, and different processing technologies.

Solve the issue of dropping powder: Compared with conductive grades, antistatic grades do not contain any carbon components. We add different amounts of antistatic agents to form ESD plastic materials to achieve the static discharge function, so this completely prevents and solves the problem of powder loss. In addition, the initial color of antistatic grades is a natural or light color, and masterbatch or color powder can be added to easily color it.

Lightweight structure: Carbon fiber reinforced plastic uses carbon fiber, a substance with high strength, high modulus, and low density, to replace traditional heavier materials, thereby achieving a significant reduction in the weight of the overall structure or product, achieving the effect of replacing metal with plastic, while still maintaining or improving the required performance and strength. Carbon fiber has excellent mechanical properties, and its specific strength (ratio of strength to density) and specific modulus (ratio of modulus to density) are much higher than many common metal materials. This lightweight realization of ESD plastics materials can not only reduce energy consumption and improve the fuel efficiency or cruising range of transportation vehicles, but also bring a series of advantages in many fields such as aerospace, automotive industry, sporting goods, etc., such as increasing payload, improving sports performance, and reducing operating costs.

Diversification of formulas: Modified materials are obtained by processing and changing raw materials through various methods and means to obtain new ESD plastic materials with various properties and characteristics. These modification methods include but are not limited to chemical modification, such as graft copolymerization, cross-linking reaction, etc., to change the molecular structure and chemical properties of the material; the modified materials show diversified characteristics in performance, such as enhanced mechanical properties (strength, toughness, hardness, etc.), improved thermal properties (heat resistance, thermal conductivity, etc.), optimized electrical properties (conductivity, insulation, etc.), improved corrosion resistance, increased flame retardancy, etc.