In today’s electronics-driven world, protecting sensitive components from electrostatic discharge (ESD) is not just a best practice—it’s a necessity. Conductive PVC compounds have become a vital material in the fight against ESD, offering tailored solutions for anti-static packaging, handling systems, and electrical components. These advanced materials help maintain product integrity, improve safety, and meet industry standards across sectors.

Why Conductive PVC Matters for ESD Protection

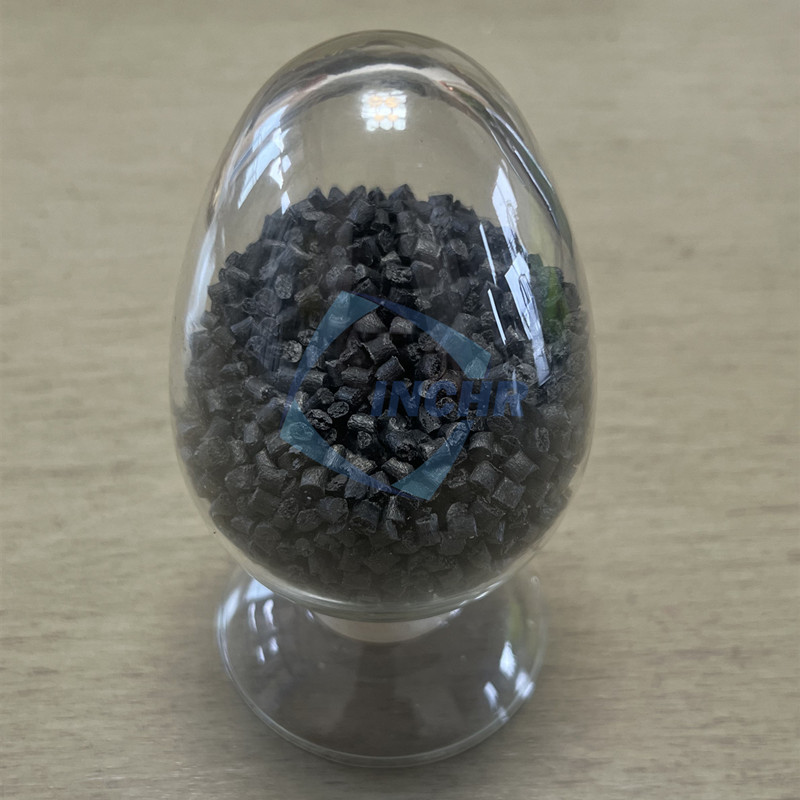

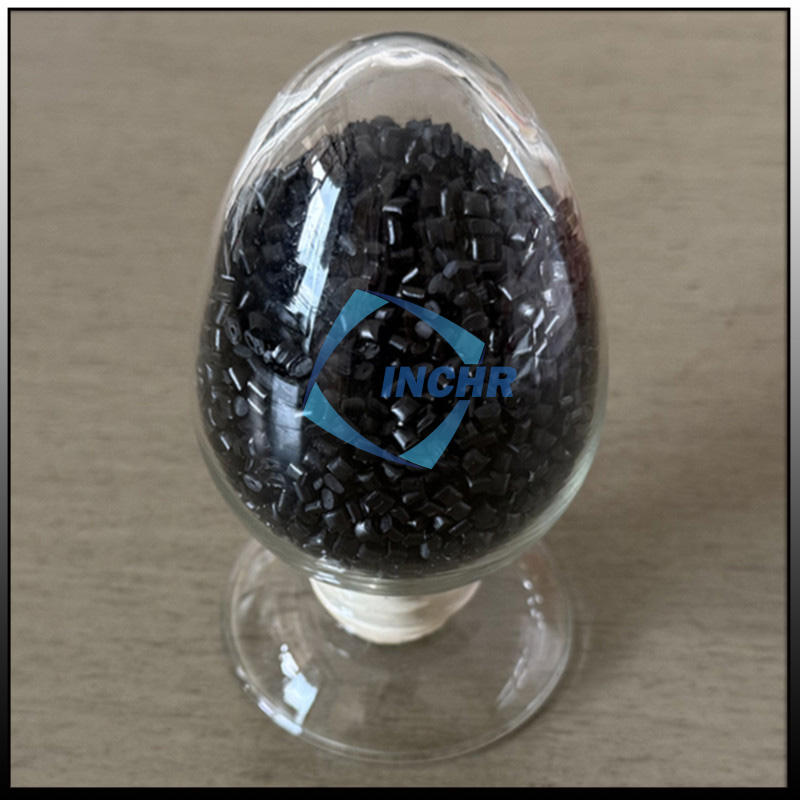

Electrostatic discharge can instantly damage microchips, circuit boards, and other electronic parts during manufacturing, storage, or transport. Traditional plastics are insulators and can accumulate static charges, increasing ESD risk. Conductive PVC compounds are formulated by adding conductive fillers (e.g., carbon black, carbon fibers, or metallic particles) to polyvinyl chloride, resulting in materials that offer controlled resistivity and dissipate static charges safely.

Key Applications of Conductive PVC

1. Anti-Static Packaging

Conductive PVC is widely used in packaging solutions for electronic components, medical devices, and explosive environments. Totes, boxes, films, and foam made with conductive PVC provide a protective Faraday cage effect, shielding contents from external electrostatic fields.

Learn more about ESD-safe packaging guidelines here

2. ESD-Safe Workspace Products

From workbench mats to floor tiles and storage containers, conductive PVC helps create ESD-protected areas (EPAs). Its durability, cleanability, and consistent conductivity make it ideal for environments where even minimal static buildup can cause damage.

3. Electrical Components and Housings

Many electrical enclosures, connector housings, and switch components are made with conductive PVC to prevent static accumulation and shield against electromagnetic interference (EMI). This is critical in automotive electronics, industrial sensors, and consumer devices.

4. Material Handling Equipment

Conductive PVC is used in conveyor belts, hoppers, and tubing where static dissipation is necessary to prevent sparks, product sticking, or contamination in sensitive settings such as chemical processing or electronics assembly.

Benefits of Using Conductive PVC

Permanent Conductivity: Unlike topical anti-static coatings, conductive PVC offers built-in, permanent static control without wearing off.

Customizable Properties: Manufacturers can adjust surface resistivity (typically between 10³–10⁶ Ω/sq) to match specific needs, whether for dissipative or more highly conductive applications.

Chemical and Abrasion Resistance: PVC’s innate resistance to oils, acids, and physical wear makes it suitable for industrial use.

Cost Efficiency: It provides an affordable alternative to metalized containers or composite materials while being lighter and easier to fabricate.

Innovations and Future Directions

New developments in nanofillers like graphene and carbon nanotubes are enhancing the conductivity and mechanical strength of conductive PVC compounds. These innovations allow for lower loading levels of conductive additives, improving flexibility and visual appeal (e.g., lighter colors for better product identification). As IoT and miniaturized electronics grow, so will the demand for smarter, higher-performance ESD materials.

Conclusion

Conductive PVC compounds play an indispensable role in modern manufacturing and electronics protection. By integrating ESD safety directly into packaging and component design, industries can significantly reduce failure rates, enhance reliability, and ensure compliance with international standards. For anyone involved in producing, handling, or packaging electronic devices, conductive PVC is a material worth understanding and implementing.