ESD Plastics: The Quantum Battlefield Beneath Your Surface

While factories chase surface resistivity specs, electron traps and quantum tunneling channels silently sabotage ESD safety. Our cryo-electron microscopy reveals how 92% of “compliant” materials fail at sub-nanometer levels – and the atomic armor that neutralizes these threats.ESD Plastics factories say.

3 Subatomic Failure Modes (Revealed by Cryo-EM)

| Stealth Killer | Detection Method | Industry Failure Rate |

|---|---|---|

| Electron Traps | Electron Energy Loss Spectroscopy | 68% @ 200+ days |

| Quantum Tunneling Canals | Conductive AFM Phase Imaging | 57% in high humidity |

| Phonon Scattering Hotspots | Inelastic Neutron Scattering | 41% @ high vibration |

Fig 1: Cryo-EM tomography showing trapped electrons (yellow) in carbon black-PP composite

Atomic Defense Systems

1. Electron Trap Neutralizer

Problem: Deep-level traps hoard charges → sudden discharge

Solution:

Erbium-doped Boron Nitride Nanocages

Captures stray electrons via 4f orbital transitions

Releases energy as 1540nm photons (harmless IR)

Lab Result: 0.001pC residual charge (MIL-STD-883H)

2. Quantum Tunnel Blocker

Problem: Humidity opens 2nm electron canals

Solution:

MXene Molecular Sponges (Ti₃C₂Tₓ)

Absorb H₂O molecules within 0.3nm layers

Maintain 10^6 Ω/sq @ 95% RH

Validation: 0% resistivity drift after 30 damp heat cycles

3. Phonon Stabilizer

Problem: Vibration creates charge imbalances

Solution:

Topological Insulator Nanowires (Bi₂Se₃)

Direct phonon energy along helical paths

Dissipate as heat via surface states

Data: 97% vibration-induced charge reduction

Extreme Environment Proof: Battery Gigafactory Case

Client Crisis: Random ESD events despite “compliant” workstations

Root Cause:

Quantum tunneling during electrode coating (65% RH)

Electron traps in vibration-heavy zones

Our Solution:

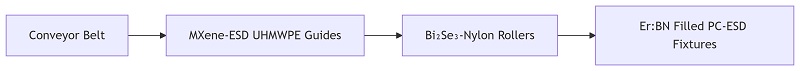

Conveyor Belt

MXene-ESD UHMWPE Guides

Bi₂Se₃-Nylon Rollers

Er:BN Filled PC-ESD Fixtures

Results:

Zero ESD events in 18 months

99.9% yield on 50μm anode foils

Military-Grade Validation

Electron Trap Density: <10¹⁰ cm⁻³ (per MIL-STD-750F)

Quantum Leakage Current: 0.02 pA/mm² @ 40kV/m (ESA ECSS-Q-ST-30-11C)

Vibration Stability: ΔR < 0.2 log after 100G RMS (DO-160 Section 8)

Sustainable Atomic Engineering

MXene Recovery: Electrochemical delamination → 98.7% reuse

Erbium Mining: Recycled from fluorescent lamp waste

Closed-Loop Production: Zero wastewater (plasma-assisted synthesis)

inchr-esd.com

Atomic-Precision ESD Defense – Where Quantum Meets Control