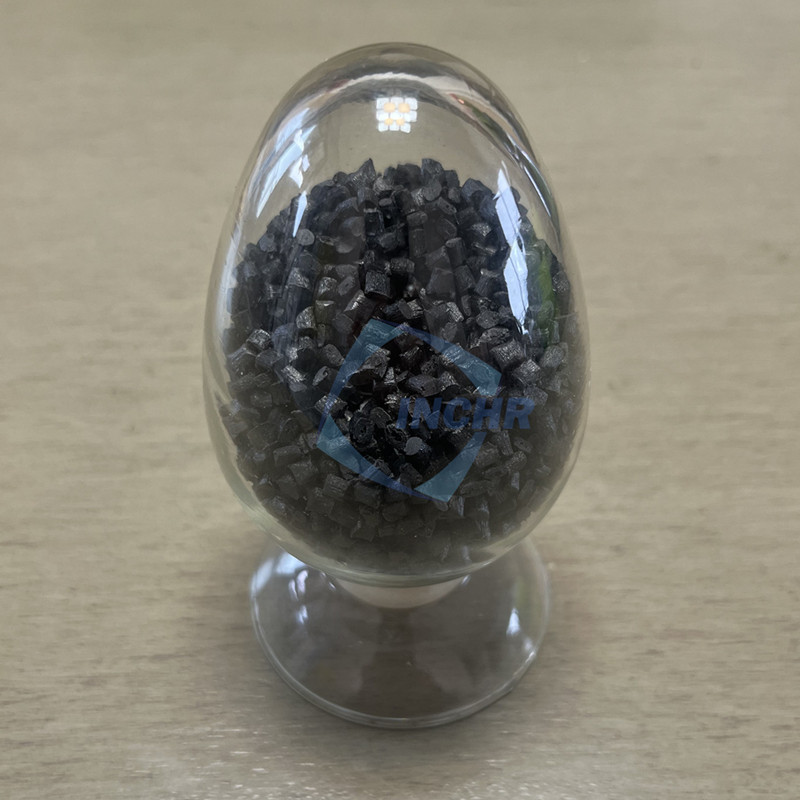

INCHR@Carbon fiber reinforced PC (polycarbonate), as a high-performance composite material, is gradually emerging and stands out among many carbon fiber composite materials with its excellent performance advantages. In recent years, the application of this material in the fields of semiconductors, electronic appliances, and automobile manufacturing has become more and more extensive, and it is highly favored by the market and industry.

The perfect combination of carbon fiber and PC

Carbon fiber: the “soul” of carbon fiber composite plastic

Carbon fiber has become the “darling” in the field of materials science with its high strength, high modulus, high-temperature resistance, corrosion resistance, fatigue resistance, creep resistance, electrical conductivity, heat transfer, and other remarkable properties. It is the “new darling” in the field of carbon fiber reinforced plastics and has many unique properties. This typical high-tech product was originally used mainly for the preparation of advanced composite materials (ACM) and has been used in the aerospace field to help aircraft break down performance limits and achieve more efficient flight. With the development of technology and the reduction of costs, its application areas are constantly expanding. In the field of sports goods, it makes sports equipment lighter and stronger, improving the performance of athletes; in the industrial field, it provides more reliable material options for mechanical equipment; in the field of transportation, it helps vehicles achieve lightweight and reduce energy consumption.

PC resin: Basic material with excellent comprehensive performance

PC, or polycarbonate, is a thermoplastic engineering plastic with excellent comprehensive performance. It has good mechanical properties, is tough and durable, and can withstand a certain degree of external force impact; it has excellent impact resistance and is not easy to break when hit; it has good heat resistance and can maintain stable performance under certain high-temperature environments. These advantages make PC widely used in many fields such as electronics, automobile manufacturing, and building materials, and become an important member of basic materials.

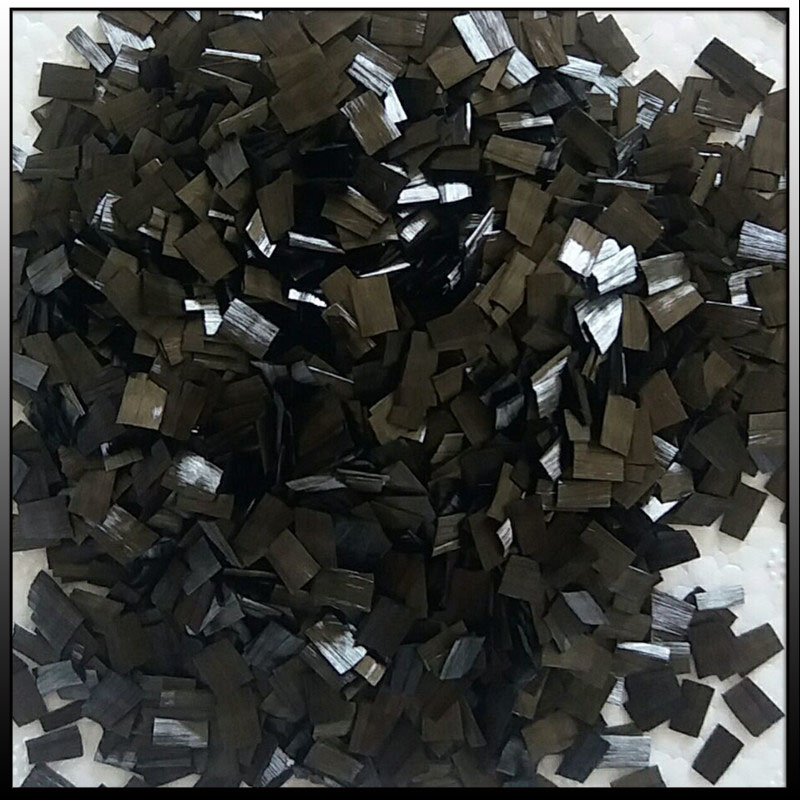

Strong combination: the birth of carbon fiber reinforced PC

When carbon fiber meets PC, a revolution in material performance begins. Carbon fiber is added to the PC matrix, and through a specific preparation process, the two are closely combined to form a carbon fiber reinforced PC composite material. This composite material combines the advantages of carbon fiber and PC, achieves a leap in performance, and provides the possibility of meeting various high-end application needs.

Unique performance advantages are fully demonstrated

Mechanical properties are greatly improved

- Significantly enhanced tensile and bending strength: In the fiber-reinforced thermoplastic composite system, carbon fiber is like a strong skeleton, using its high strength to bear the main stress of the composite material, while the PC matrix is like a flexible muscle, transferring stress through plastic flow and adhesion with the fiber interface. With the increase in carbon fiber content, the tensile strength, bending strength, and bending modulus of PC materials are significantly improved. Compared with pure PC (tensile strength of about 63MPa, bending modulus of about 2300MPa), when 2% carbon fiber is added, the tensile strength and bending modulus increase by 12% and 60% respectively. This makes carbon fiber reinforced PC perform better when subjected to tensile and bending forces and can be used in structural components with higher strength requirements.

- Changes in notched impact strength: The notched impact strength shows a trend of increasing first and then decreasing with the increase of carbon fiber. When the carbon fiber content is 6%, the impact strength reaches the maximum value, because at this time the contribution of resin deformation in the notched impact strength of the composite material is dominant. However, when the content exceeds 6%, the impact strength decreases rapidly, and the rate of decrease slows down when it reaches 8%. This is because the carbon fiber content is too high and the resin content is reduced, which makes it easier to extract the fiber from the resin. The ends of the carbon fiber will become the initiation point for crack growth, thereby reducing the impact strength and elongation of the material. Nevertheless, within the appropriate range of carbon fiber content, the impact performance of carbon fiber reinforced PC is still better than many traditional materials.

- Beyond the effect of glass fiber reinforcement: Under the same conditions, INCHR@Carbon fiber reinforced PC significantly exceeds glass fiber reinforced PC in mechanical properties such as tensile strength, flexural strength, and flexural modulus. This makes carbon fiber reinforced PC more advantageous in application scenarios that require demanding mechanical properties of materials and can meet higher standards of design and use requirements.

Significant improvement in antistatic properties

When the added carbon fiber content is 10%, the surface resistivity has reached 10E10 Ω, which can be used as an antistatic material; when added 15%, the conductivity of the composite material has been significantly improved, and the surface resistance value is less than 10E5 Ω. This feature enables carbon fiber reinforced PC to quickly conduct away charges and eliminate the safety hazards caused by static electricity.

Processing performance optimization

After adding carbon fiber, the situation is significantly improved. The fluidity of PC with only 2% carbon fiber added is nearly doubled compared to pure PC (melt index of about 17g/min) because carbon fiber improves the adhesion between PC and metal. However, as the carbon fiber content increases further, the friction between molecules in the melt between molecules and carbon fiber, and between carbon fiber and carbon fiber gradually increases, and the fluidity gradually decreases. Therefore, in actual processing, it is necessary to select the appropriate carbon fiber content according to specific needs to balance the performance and processing performance of the material.