Introduction

Carbon Fiber Reinforced Plastic (CFRP) isn’t just another composite material—it’s the backbone of 21st-century engineering innovation. From Boeing 787 Dreamliners to Formula 1 race cars, CFRP delivers unprecedented strength-to-weight ratios, corrosion resistance, and design flexibility. This deep dive explores why industries globally invest billions in CFRP technology.

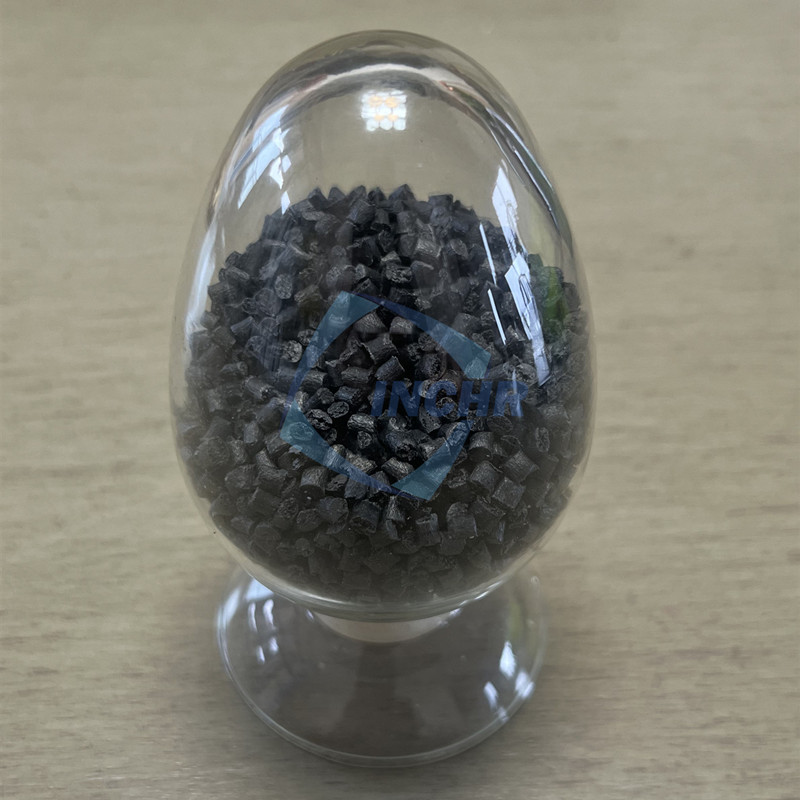

What Exactly is Carbon Fiber Reinforced Plastic?

CFRP combines two primary components:

Reinforcement: Carbon fibers (5-10μm diameter) providing tensile strength

Matrix: Thermosetting polymers (typically epoxy) binding fibers

The magic lies in the fiber alignment. Unidirectional layups offer 1500 MPa strength in load direction, while woven fabrics provide multi-axis stability.

5 Game-Changing Properties of Carbon Fiber Reinforced Plastic

Density (1.6 g/cm³) vs. Aluminum (2.7 g/cm³):

40% lighter than aluminum, 60% lighter than steel at equal strength

Airbus A350 uses 53% CFRP, saving 25,000 liters of fuel annually

Tensile Strength (3,500 MPa)

Exceeds high-grade steel (1,200 MPa) by 3x

Critical for wind turbine blades exceeding 100m length

Fatigue Resistance

CFRP withstands 10⁷ stress cycles vs. aluminum’s 10⁵

Thermal Expansion Coefficient (0.5×10⁻⁶/K)

Near-zero thermal deformation vs. aluminum (23×10⁻⁶/K)

Essential for satellite components in extreme orbital temperature swings

X-Ray Transparency

Enables medical imaging equipment housings without signal interference

Manufacturing Breakthroughs Driving Adoption

Automated Fiber Placement (AFP)

Robotic arms lay 20kg of carbon tape/hour with 0.1mm precision, slashing Boeing 787 fuselage production time by 30%.

Out-of-Autoclave (OOA) Curing

New epoxy systems cure at 135°C (vs. traditional 180°C), reducing energy costs by 60% and enabling larger components.

Real-World Applications Transforming Industries

| Industry | CFRP Application | Impact |

|---|---|---|

| Aerospace | Wing boxes, fuselages | 20% aircraft weight reduction |

| Automotive | Chassis, battery enclosures | 200km extra EV range per tonne saved |

| Wind Energy | Turbine blades | Enables 100m+ blades for 15MW turbines |

| Medical | MRI coils, prosthetics | 30% lighter orthopedic devices |

| Sports | Bicycle frames, tennis rackets | 18% faster vibration damping |

The Cost Challenge: Why Carbon Fiber Reinforced Plastic Remains Premium

Raw material costs tell the story:

Aerospace-grade carbon fiber: $60/kg

Automotive steel: $1/kg

But new solutions are emerging:

Recycled CFRP: Siemens Gamesa’s recyclable blades recover 95% fibers

High-Speed Compression Molding: Toyota’s 5-minute cycle CFRP hood production

Sustainability Innovations

Circular Economy Models:

Pyrolysis recycling at 700°C recovers undamaged fibers

Solvolysis dissolves resin with supercritical fluids

Remanufacturing: Airbus reuses CFRP scraps for cabin partitions

Future Frontiers (2024-2030)

Self-Healing CFRP: Microcapsules release healing agents upon crack detection

Nanotube-Enhanced CFRP: 30% improved electrical conductivity for EV components

AI-Driven Design: Generative algorithms creating topology-optimized CFRP parts

3 CFRP Selection Mistakes to Avoid

Ignoring Anisotropy: Forgetting directional strength variations leads to premature failure

Galvanic Corrosion: Using CFRP with aluminum without insulation causes rapid degradation

Overlooking CTE Mismatch: Bonding CFRP to metals requires compliant adhesives

Conclusion: The Composite Dominance Era

As Carbon Fiber Reinforced Plastic production costs plummet 8% annually (BloombergNEF 2023), its penetration will grow beyond current $25B market value. From hydrogen storage tanks to lunar habitats, this material transcends conventional engineering limits. The question isn’t if but how fast your industry will adopt CFRP.