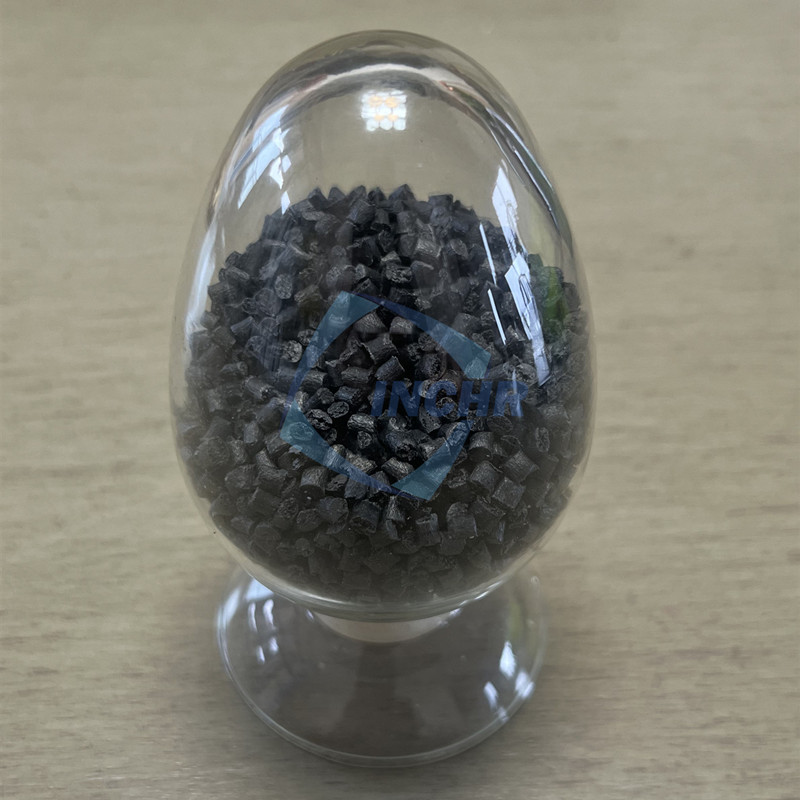

In the world of high-performance engineering plastics, carbon fiber reinforced nylon (CFR nylon) stands out as a material that combines lightweight properties with exceptional strength and durability. Whether you’re designing automotive components, aerospace parts, or industrial machinery, understanding the advantages and applications of CFR nylon can help you make smarter material choices. This article explores the science behind carbon fiber reinforced nylon, its key benefits, real-world uses, and how to select the right grade for your project.

Nylon (Polyamide): Known for its toughness, wear resistance, and thermal stability.

Carbon Fiber: Adds high tensile strength, stiffness, and dimensional stability.

This synergy creates a material ideal for industries requiring precision, durability, and weight reduction.

Key Benefits of CFR Nylon

1. Lightweight yet Strong

CFR nylon offers a strength-to-weight ratio comparable to metals like aluminum, making it perfect for applications where reducing mass is critical (e.g., automotive and aerospace).

2. Chemical and Wear Resistance

Resistant to oils, fuels, and solvents, CFR nylon excels in harsh industrial settings. Its low friction coefficient also reduces wear over time.

3. Dimensional Stability

Carbon fibers minimize thermal expansion, ensuring parts maintain shape under stress or temperature fluctuations.

Applications of Carbon Fiber Reinforced Nylon

1. Automotive Industry

Gear components

Engine covers

Lightweight structural brackets

2. Aerospace

Drone frames

Satellite components

Interior cabin parts

3. Industrial Machinery

Bearings

Conveyor system parts

Robotic arms

4. Consumer Electronics

Durable casings for tools

Heat-resistant connectors

How to Choose the Right CFR Nylon

Selecting the optimal grade depends on your project’s requirements:

Temperature Range: Ensure the material’s heat resistance aligns with operational conditions.

Chemical Exposure: Verify compatibility with oils, solvents, or acids.

Mechanical Loads: Higher carbon fiber content (30-40%) suits heavy-load applications.

Cost Efficiency: Balance performance needs with budget constraints.

Future Trends in CFR Nylon Technology

Innovations like recycled carbon fiber and 3D printing compatibility are expanding CFR nylon’s sustainability and design flexibility.

Conclusion

Carbon fiber reinforced nylon is a game-changer for industries prioritizing strength, weight savings, and durability. By understanding its properties and applications, engineers and designers can unlock new possibilities for innovation.

When sourcing CFR nylon, partner with suppliers who provide certified material data sheets and customization options to meet your specific needs.