In the world of advanced engineering materials, carbon fiber reinforced nylon (CFRN) stands out as a game-changer. Combining the versatility of nylon with the strength of carbon fibers, this composite material delivers unmatched performance for demanding applications. Whether you’re in aerospace, automotive, or consumer product design, understanding CFRN could unlock innovative solutions for your projects. Let’s dive into why this material is making waves.

What Is Carbon Fiber Reinforced Nylon? | Product Catalog

Carbon fiber reinforced nylon is a composite polymer created by embedding carbon fibers into a nylon matrix. The result? A material that retains nylon’s lightweight, flexible, and corrosion-resistant properties while gaining exceptional strength, stiffness, and thermal stability from the carbon fibers. Typically, carbon fibers make up 10-40% of the composite, depending on the desired performance characteristics.

How Is CFRN Manufactured?

The production process involves two key steps:

Fiber Preparation: Carbon fibers are chopped or woven into short strands to ensure even distribution within the nylon base.

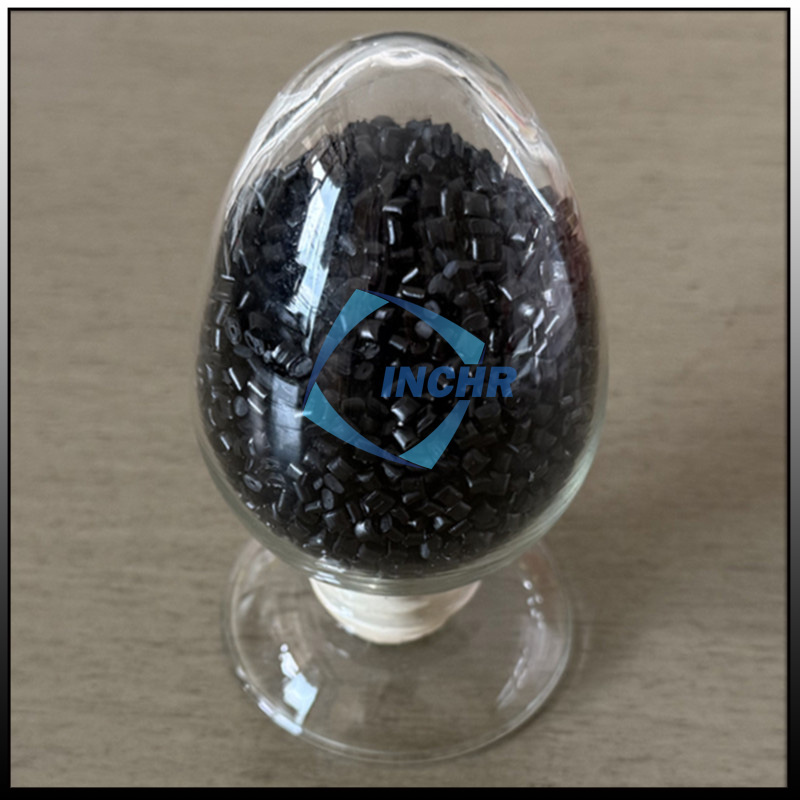

Compounding: The fibers are mixed with molten nylon (usually PA6 or PA66) using extrusion or injection molding techniques. This creates pellets ready for manufacturing end-use parts.

Advanced techniques like 3D printing are also gaining traction, enabling complex geometries that traditional methods can’t achieve.

Key Advantages of CFRN

1. Superior Strength-to-Weight Ratio

CFRN’s up to 50% lighter than aluminum yet rivals its strength, making it ideal for weight-sensitive industries like aerospace and automotive.

2. Enhanced Thermal Resistance

With a heat deflection temperature (HDT) exceeding 200°C, CFRN outperforms standard nylons in high-temperature environments.

3. Chemical and Moisture Resistance

Nylon’s inherent resistance to oils, solvents, and humidity is preserved, ensuring durability in harsh conditions.

4. Design Flexibility

Suitable for injection molding, extrusion, and additive manufacturing, CFRN adapts to intricate designs without sacrificing performance.

5. Cost Efficiency

While pricier than unfilled nylon, CFRN reduces long-term costs by minimizing part failures and replacements.

Top Applications of Carbon Fiber Reinforced Nylon

Aerospace: Lightweight brackets, drone components, and UAV parts.

Automotive: Engine covers, gear housings, and electric vehicle battery mounts.

Industrial: Robotic arms, conveyor system parts, and machinery housings.

Consumer Goods: High-performance sporting equipment, durable phone cases, and wearables.

Medical: Sterilizable surgical tools and imaging device components.

Choosing the Right Carbon Fiber Reinforced Nylon Grade

Consider these factors when selecting a grade:

Fiber Content: Higher fiber percentages improve strength but reduce ductility.

Nylon Type: PA6 offers better impact resistance; PA66 provides higher thermal stability.

Post-Processing Needs: Some grades require annealing to minimize warping.

Pro Tip: Work with suppliers to test prototypes under real-world conditions before full-scale production.

The Future of Carbon Fiber Reinforced Nylon

Innovations in recycled carbon fibers and bio-based nylons are pushing CFRN composites toward sustainability. Meanwhile, advancements in AI-driven design tools are optimizing fiber alignment for even stronger, lighter parts. As industries prioritize efficiency and eco-friendliness, CFRN’s poised to remain a critical material.

Conclusion

CFRN bridges the gap between traditional plastics and high-end metals, offering a cost-effective solution for modern engineering challenges. By leveraging its unique blend of strength, lightweight properties, and adaptability, businesses can create durable, high-performance products that meet evolving market demands.