In the long history of materials science’s evolution, a quiet but far-reaching change is booming plastics, especially carbon fiber reinforced plastics, are gradually emerging, challenging the dominance of traditional steel and expected to reshape the future pattern of many industries.

1. Characteristics of carbon fiber reinforced plastics injection molding

Carbon fiber reinforced plastic injection molding (Carbon Fiber Reinforced Plastics Injection, referred to as CFRPI), is a new injection molding grade material that is a sophisticated combination of high-strength carbon fiber and high-performance plastic matrix. Carbon fiber is like a “steel bone” in the microscopic world. Its diameter is usually between 5-10 microns, but it has an extraordinary tensile strength of up to 3500-6000 MPa, far exceeding the 250-700 MPa of ordinary steel, which means that it can be tenacious and not easy to break when subjected to huge tensile forces. At the same time, its density is only about 1.5-2.0 g/cm³, which is as light as a”featherweight” compared to the heavy steel of 7.8 g/cm³, opening the door to applications that pursue lightweight.

From the perspective of chemical stability, CFRPI performs well. Whether it is water vapor erosion in a humid environment, chemical corrosion of acid and alkali solutions, or long-term ultraviolet radiation “bombing” outdoors, it can remain safe and sound, greatly broadening the boundaries of use. In fields such as marine engineering equipment and chemical pipelines, traditional steel is prone to rust and corrosion, and CFRPI has become an ideal substitute. In terms of thermal performance, it has both a low expansion coefficient and good high-temperature resistance. Some high-end CFRPI products can be stably used at high temperatures of 200-300℃. It can also calmly cope with the high-temperature “baking test” encountered by aerospace vehicles when passing through the atmosphere, effectively ensuring structural integrity.

2. Disruptive applications in multiple fields

(I) Aerospace: Breaking through the bottleneck of weight

In the field of aviation, weight reduction is an eternal theme. Take the Boeing 787 as an example. Its fuselage uses a large amount of CFRP, accounting for nearly 50%. After the key parts such as wings and fuselage frames are replaced with “plastic new clothes”, the weight of the aircraft is greatly reduced, and the fuel efficiency soars by about 20%. This not only reduces operating costs and significantly reduces fuel consumption per flight, but also extends the flight range, making it possible to open up more long-distance routes, making the world truly a “global village”. Satellite manufacturing is even more of a “show” for CFRPI. The harsh environment of space requires materials to be light, rigid and radiation-resistant. CFRPI is a perfect match, helping satellites to shuttle lightly between the stars and transmit signals stably, making great contributions to global communications, meteorological monitoring, space exploration, etc.

(II) Automobile Manufacturing: Driving Towards a Green and Efficient Future

The automobile industry is moving towards the coordinated development of electrification, intelligence, and lightweight, and CFRPI has become a key “puzzle piece”. BMW i3, i8 and other new energy models use CFRPI in some body structures, which reduces the weight of the whole vehicle and increases the cruising range, making up for the shortcomings of electric vehicles’ “mileage anxiety”. Moreover, under high-speed driving and frequent start-stop conditions, a lighter body means lower energy consumption and more agile control, which enhances driving pleasure. In addition, due to the innovation of CFRPI, the automobile production process can be formed by one-piece molding technology such as injection molding and compression molding, reducing the number of parts splicing processes, shortening the production cycle, and reducing costs, paving the way for large-scale application of high-end plastic materials in automobiles.

(III) Sports equipment: Helping peak performance

Carbon fiber reinforced plastic injection molding is everywhere in the sports arena. After high-end bicycle frames use it, the weight can be reduced to about 1 kg, allowing riders to accelerate with less effort, climb hills as if walking on flat ground, and speed up in top events such as the Tour de France. Tennis rackets, golf clubs, etc. introduce carbon fiber reinforced plastics, which can transmit energy efficiently and accurately at the moment of hitting the ball, allowing athletes to control strength and direction more freely, impact the limits of sports, and repeatedly achieve good results. It also allows amateurs to enjoy a better sports experience and promote the national fitness craze.

(IV) Household items: Widely used

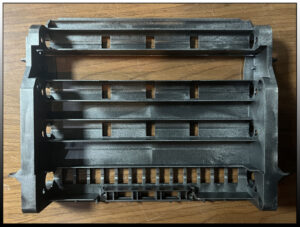

CFRPI nylon based is used in tables, chairs, cabinets, etc., it is lightweight, high-strength, durable, and has a unique appearance. CFRPI PPS is used in door and window frames which is light and durable, with good sealing, heat insulation, and anti-theft performance. Floor and wall decoration and kitchen and bathroom equipment have corrosion resistance and high-temperature resistance. CFRPI can be used to make curtains, storage boxes, etc. The curtains have a unique texture and the storage boxes are strong and pressure-resistant.

3. Recycling

Researchers optimize the carbon fiber preparation process and develop new low-cost raw fiber production technologies, such as biomass-based raw fiber exploration, which is expected to reduce raw material costs by 30% – 50%; on the other hand, innovative recycling methods, chemical depolymerization, supercritical fluid extraction, and other cutting-edge technologies have emerged, which can disassemble CFRP into reusable carbon fiber and plastic raw materials, and the recycling rate has gradually increased to 60% – 80%, building a green closed loop from production to recycling, and injecting power into the sustainable development of materials.

4. About INCHR

Dongguan City INCHR New Material Co., Ltd. (INCHR) is a manufacturer of carbon fiber reinforced plastic injection molding, providing technical services from material product design and development to industrial large-scale production. INCHR has passed ISO9001 quality system certification and TS16949 automotive industry certification, focusing on carbon fiber composite plastic injection molding grade and conductive antistatic plastic, and has more than ten years of experience in the industry.