What is a migrating antistatic agent?

Migrating-antistatic agents will migrate from the inside of the material to the surface to play an antistatic role. In this process, if the migration speed is too fast or the amount used is too much, a layer of “oil frost” or “spray frost” may be formed on the surface of the material, which will affect the appearance of the material and make the surface blurry and greasy. For some products with appearance requirements, such as transparent packaging materials, optical instrument parts, etc., this is a serious quality problem. In addition, some exudation antistatic agents may react chemically with other substances in contact. If the antistatic agent migrates to the surface of another material in contact with it, it may cause adhesion or corrosion between the materials. For example, when it contacts some metal parts, it may cause metal corrosion.

What is a permanent non-migrating antistatic agent?

A permanent non-migrating antistatic agent is a chemical additive added to a polymer material that can give the material antistatic properties for a long time and stably, and will not migrate inside the material or precipitate to the surface and outside. Its working mechanism conducts and releases static electricity by forming a specific conductive structure or path inside the polymer material. For example, after polymer permanent antistatic agents are blended with the polymer matrix, the molecular chain has strong mobility, which facilitates the movement of protons, conducts static charge through ion conduction, and is distributed in fine layers or tendons on the surface of the product, forming a conductive surface to leak static charge. Permanent non-migrating antistatic agents are suitable for manufacturing high-end antistatic films, especially those that require printing. In the semiconductor packaging industry, permanent non-migrating antistatic agents are the only choice, and semiconductor electronic components cannot accept any exudates.

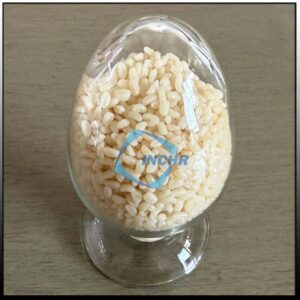

Introduction of INCHR@Permanent non-migrating antistatic agent

The full name of INCHR company is Dongguan City INCHR New Material Co., Ltd which is a permanent non-migrating antistatic agent manufacturer located in China, focusing on the research and development, production, and sales of antistatic agents. It can provide permanent antistatic agent solutions. The products are well-compatible with products and have a long-lasting antistatic effect. It has a high reputation in the field of antistatic agents. Among them, 300AN, 100AN, PS30AN, 120T, and other permanent non-migrating antistatic agents can be used for injection molding, extrusion, and cast molding. INCHR@Permanent non-migrating antistatic agent has the characteristics of not being affected by wiping and washing and excellent colorability. The products cover a variety of high-performance materials and also have a certain share in the permanent non-migrating antistatic agent market. The business involves multiple chemical fields, and the permanent antistatic agents it produces are of reliable quality and widely used. At the same time, INCHR focuses on antistatic and antistatic plastics, providing transparent permanent antistatic materials such as PET, ABS, and TPU.

Advantages of INCHR@Permanent non-migrating antistatic agent

INCHR@Permanent non-migrating antistatic agent has a long-lasting effect, and it can continuously and stably resist static electricity throughout the entire use cycle of the material, and it will not be greatly weakened due to the use process, washing, etc. It takes effect immediately and can immediately play an antistatic role after adding. It is less affected by environmental humidity and does not rely on absorbing moisture to form a conductive layer. It has good compatibility with polymer substrates and has little effect on the mechanical, optical, and processing properties of the material. It has good thermal stability and can maintain a stable chemical structure and performance under high-temperature conditions of processing and use.