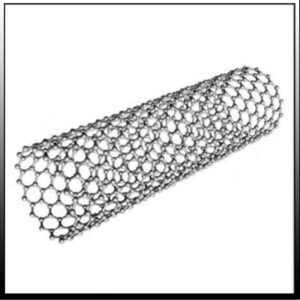

In filled conductive plastics, the plastic itself is not conductive and only acts as a structural material. Conductivity is mainly obtained by the conductive substances mixed in it, such as carbon materials, metal powders, antistatic agents, etc. These conductive substances are called conductive fillers, and they play a role in providing carriers in filled conductive plastics. Carbon-based conductive fillers that can be used in conductive plastics include carbon black, acetylene black, carbon nanotubes, graphene, etc. At present, the carbon-based conductive fillers in conductive plastics are still dominated by traditional materials such as carbon black and acetylene black. However, with the continuous development of the global manufacturing industry, the performance requirements for conductive plastics have also continued to increase, and the performance bottleneck of traditional carbon black as a conductive filler has emerged.

Main role of carbon nanotubes in conductive plastics

Significantly improve electrical conductivity

Carbon nanotubes have excellent electrical properties, and their electrical conductivity is extremely high, which can be several times that of copper, far superior to traditional conductive materials such as carbon black and graphite. Adding a small number of carbon nanotubes to plastics, usually 0.1% to 1%, can form a continuous conductive network, which can significantly improve the conductivity of plastics and achieve the same or even better conductive effects. The amount added is only that of traditional carbon black 1/5-1/15.

Enhance mechanical properties

Young’s modulus of carbon nanotubes is nearly six times that of steel, and its tensile strength is 100 times that of steel. It has extremely high elasticity and toughness. Adding carbon nanotubes to conductive plastics can not only improve the conductivity of the material but also maintain or even enhance the mechanical properties of the plastic to a certain extent, such as making the material tougher and more wear-resistant, suitable for applications that require high-strength and high wear resistance.

Improve molding fluidity

The low addition amount of carbon nanotubes can maintain the impact properties of the material and improve the molding fluidity, making it easier for the plastic to flow and fill the mold more easily during the processing and molding process, thereby greatly improving the appearance and quality of the plastic product.

Achieve high transparency and appearance optimization

Since the dosage of single-walled carbon nanotubes is generally 0.01%~0.1%, it can produce any color and transparent conductive materials, which can meet the requirements for material appearance and transparency in modern design, such as in the casings and displays of some electronic devices. In components, the material needs to be conductive, and the appearance is also required to be beautiful(single-walled carbon nanotubes only).

Improve thermal and chemical stability

Carbon nanotubes feature excellent thermal conductivity and chemical resistance. They have high axial thermal conductivity and can withstand extreme environmental conditions such as temperature and pressure. Adding carbon nanotubes to conductive plastics can improve the thermal stability of the plastic and prevent the material from deforming or failing at high temperatures. It can also improve the acid and oxidation resistance of the material itself so that it can still maintain good performance in harsh chemical environments.

Provide electromagnetic shielding

Carbon nanotubes have special electromagnetic properties and can absorb and reflect electromagnetic waves. When it is added to plastic to make conductive plastic, the plastic can have a certain electromagnetic shielding ability. In the fields of electronic equipment, communication equipment, aerospace, and other fields, it can effectively prevent electromagnetic interference and electromagnetic leakage, and protect the normal operation and safety of equipment. Information security.

Application cases of carbon nanotubes in conductive plastics

Carbon nanotube-reinforced conductive ABS

Carbon nanotubes have excellent electrical properties and extremely high conductivity. Adding a small amount of carbon nanotubes to ABS can form a continuous conductive network, significantly improving the conductive properties of the material, making ABS Anti-static, electromagnetic shielding, and other functions. Carbon nanotubes have extremely high Young’s modulus and tensile strength. While improving the conductivity of ABS, they can also maintain or even enhance its mechanical properties to a certain extent, such as impact strength, tensile strength, and bending strength, making the material Tougher and more wear-resistant. The low addition amount of carbon nanotubes can maintain the impact properties of the material and improve the molding fluidity, making it easier for the carbon nanotube conductive ABS to flow and fill the mold during the processing and molding process, improving production efficiency and product quality.

Carbon nanotube-reinforced conductive polycarbonate (PC)

Carbon nanotube reinforcement realizes functions such as anti-static and electromagnetic shielding. Its surface resistance can reach 10E5 to 10E9 Ω, which can meet the requirements of electrostatic protection and electromagnetic shielding for a variety of electronic equipment. Electromagnetic compatibility requirements. Carbon nanotubes have extremely high Young’s modulus and tensile strength, which can enhance the mechanical properties of PC to a certain extent, such as impact strength, tensile strength, and bending strength, making the conductive compound tougher, wear-resistant, glossy, and other original characteristics. Carbon nanotubes themselves have good thermal stability, they can increase the thermal deformation temperature and thermal stability of conductive polycarbonate, allowing it to maintain stable performance over a wide temperature range and meet the requirements for use in high-temperature environments.