Introduction of ESD Polycarbonate

ESD Polycarbonate (PC) is a polycarbonate material specially treated or added with an antistatic agent.

Ordinary PC materials may accumulate static electricity in some cases, in contrast, antistatic PC reduces its surface resistance through specific means, making it capable of inhibiting or reducing the generation and accumulation of static electricity.

ESD Polycarbonate has some excellent properties of PC itself, such as high strength, toughness, heat resistance, etc., and also has antistatic properties. It is widely used in some fields that are sensitive to static electricity, such as the electronic and electrical industry, where it can be used to manufacture parts and shells that need to prevent static interference or damage; it can also play a role in some occasions where clean environment requirements are high, avoiding the adsorption of dust and other impurities due to static electricity.

Applications of ESD Polycarbonate

The performance advantages of ESD Polycarbonate are mainly reflected in the following applications:

- Electronic equipment field: used to manufacture the shells of electronic products such as computers and mobile phones, which can reduce the interference and damage of static electricity to internal electronic components, and also prevent static electric shock when the human body touches them.

- Precision instrument manufacturing: such as some high-precision measuring instruments, the antistatic performance can ensure that the accuracy of the instrument is not affected by static electricity.

- Medical equipment: avoid the potential safety hazards caused by static electricity or interference with sensitive medical equipment.

- Semiconductor industry: used in the manufacture of related components in the production process, which helps to maintain static control in the production environment.

- Clean room environment: prevent static electricity from adsorbing dust and particles and maintain the cleanliness of the environment.

- Packaging materials: It can ensure product safety, especially for static-sensitive product packaging.

- Automotive interior: reduce static electricity generation and improve riding comfort and safety.

Classification of ESD Polycarbonate

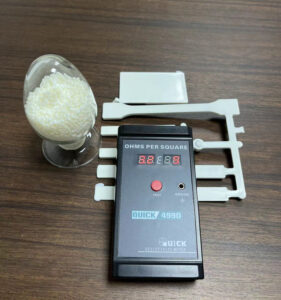

- Adding antistatic agent: Adding antistatic agent to PC resin can be a permanent antistatic agent. The antistatic agent forms a water film on the product’s surface by adsorption to prevent the generation and accumulation of static electricity. INCHR@Polycarbonate permanent antistatic agent is well compatible with polycarbonate resin and minimizes the impact on its mechanical properties.

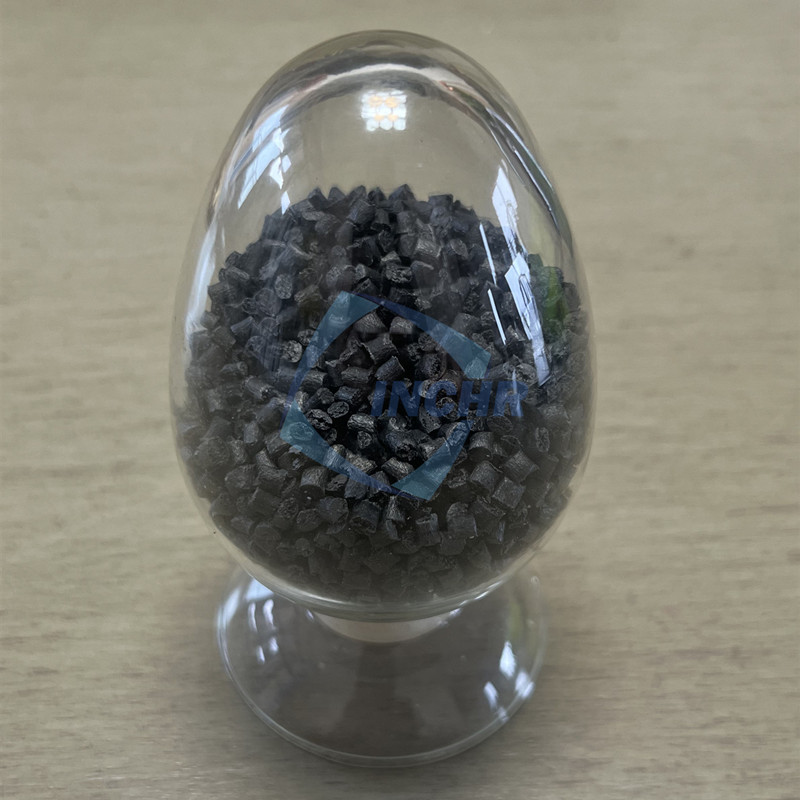

- Forming a conductive channel: Dispersing conductor masterbatch, carbon fiber, stainless steel fiber, or semiconductor inorganic material into the PC matrix to form ESD Polycarbonate and conducting electricity through the ribs or mesh paths formed by these materials, so that the product has an antistatic effect.

- Surface treatment: The PC surface is specially treated by electroplating or spraying to form an antistatic hard film, which perfectly retains the inherent physical properties of the substrate and has excellent antistatic function.